brewery ventilation requirements

You are using an out of date browser. In 1996, a fire broke out at Heaven Hill Distillery, also located in Bardstown, and burning whiskey created what one employee described to The Kentucky Standard as a river of fire. In 2000, a fire at a Wild Turkey distillery in Lawrenceburg destroyed nearly 1 million gallons of bourbon. OSHA rules on respiratory protection can also come into play, as malt dust is irritating to the lungs and mucous membranes. electric brewery, You also acknowledge that this forum may be hosted outside your country and you consent to the collection, storage, and processing of your data in the country where this forum is hosted. Thats something you didnt plan for when you designed your brewery and it will certainly lead to problems.

Hot and cold hose bibs are required in all brewery spaces and lab areas. This is a problem, says Gittleman, a longtime NFPA member.

A feature common to almost every craft distillery is a tasting room, where visitors of legal drinking age can sip free or inexpensive samples of the business's products. the project located in NYC.  Thank you Drazen.

Thank you Drazen.

It may not display this or other websites correctly. The fermentation process produces a large amount of CO2. Please consider upgrading! If our team is performing the installation of your brewery system, we want to ensure the process is performed as efficiently and effectively as possible. Due to the nature of the brewing process, walls and ceilings should be washable.

While Gittleman has pointed clients to the document in the past, he has become so concerned about liability issues related to fire safety at distilleries that he no longer accepts them as clients.

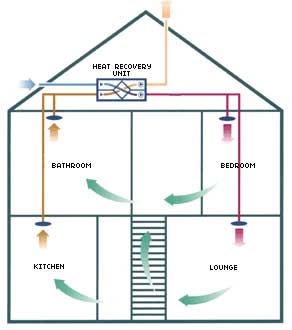

Determine the refrigeration systems classification, in accordance with Section 1103.3. (fixture type, location and quality) Sanitary fixture requirements for customers and employees shall be permitted to be met with a single set of restrooms. Make-up air is required in the boiler room on a steam-fired system and in the brewhouse area for a direct gas-fired system.

By clicking "I AGREE" below, you agree to our Privacy Policy and our personal data processing and cookie practices as described therein. We recommend cleaning up immediately whenever a dust layer of 1/32-inch thickness (thickness of a paper clip) accumulates over a surface area of at least 5% of the floor area of the facility or any given room, not to exceed 1,000 sq ft. Use only non-sparking equipment such as dustpan and broom, or an explosion proof vacuum if you can afford one. The brewery is most likely operating with venting from the vat directly to the atmosphere. OSHA rules on respiratory protection can also come into play, as malt dust is irritating to the lungs and mucous membranes. At the low end is a completely enclosed boiler of the type you would see in a craft brewery. Well according to a recent BYO article by John Blichmann the rule of thumb is to have a minumum of 34 cubic feet/min per kilowatt (952 l/min per kw) of heater required.

This should be confirmed by sampling the actual vapor concentration under normal operating conditions, the document reads. Login.

In a closed space you will get heavy condensation on the ceiling, walls, windows, floors and even between walls. The FM Global research shows that, while fire sprinklers are typically effective at suppressing flames for rack-stored spirits where barrels are stored on their sides, wide flue spaces are essential in palletized configurations where barrels are stored upright.

Based on the information that I provided you, you'll need a ventilation rate of at least 33,845 cu.ft./hr under steady state conditions.

One area I'm unsure of is ventilation for my fermentation room.

brewing, not the same. In 1996, FM Global, whose clients include whiskey makers, began research into fire protection and storage configurations for distilled spirits about five years ago. JavaScript is disabled.

6848 Kirkpatrick Cres. 109 0 obj << /Linearized 1 /O 111 /H [ 1030 684 ] /L 227204 /E 63785 /N 13 /T 224905 >> endobj xref 109 28 0000000016 00000 n 0000063327 00000 n This not only sent rivers of burning alcohol down the street, but caused a dangerous build-up of fumes within the building, according to The Herald, a Scottish newspaper. I'm sure it is documented somewhere. Photographs: Top, Angelo Verzoni; Bottom, NFPA Conference & Expo Presentation, Rack-stored Distilled Spirits Storage Protection 2018 FM Global. In part 1 of this series I covered some of the general considerations in planning an electric brewery including size of the system, availability of water and in particular the electrical needs of the system and electrical safety considerations.

A good rule of thumb is that youll need 1 Ton of cooling per 150SF of Taproom and 1 ton of cooling per 300SF of production brewing space (if conditioned). IN 2003, A LIGHTNING STRIKE AT A JIM BEAM warehouse in Bardstown, Kentucky, set the wood-frame structure ablaze and sent 800,000 gallons of flaming bourbon into a nearby retention pond.

Your OP should have been posted in the Local Exhaust Ventilation forum. The threshold limit value (TLV) for CO2 is 5000 ppm ( ppm means parts of CO 0000007224 00000 n My concern is the elevated level of carbon dioxide during the fermentation process. Clicking login or register below will redirect you to ProBrewer.com to start your login there. Explore the Brewers Association's most high-value resources and tools in one click.

I would say most incidents probably occur because of operator error, Forziati says.

For additional details, refer to our Privacy Policy. Please state the time that it takes to complete the fermentation that produces CO2 during the batch process.

WebI am currently working on ventilation requirements for my new brewery. ventilation. We process personal data about users of our site, through the use of cookies and other technologies, to deliver our services, personalize advertising, and to analyze site activity. Your OP should have been posted in the Local Exhaust Ventilation forum. Your understanding of "significant figures" reveals something of your engineering skills. Similar scenarios have played out at other distilleries in Kentucky, which is home to many of the countrys largest whiskey makers. If a professional install is cost-prohibitive, consider using a little DIY elbow grease to save some cash. homebrew, Renew now to keep accessing exclusive seminars, industry statics, the BA forum, and much more!

As the temperature of the fire increased, the spirit casks in the warehouse had begun to rupture. Per day means 24 hours of continuous fermentation.

FM Global, whose clients include whiskey makers, began research into fire protection and storage configurations for distilled spirits about five years ago. 0000002144 00000 n Published on March 1, 2018.

This will be expensive. 456.3587 Total pounds of CO2 released per day at full capacity. Tagged as: please help how many Air changer per hour required to be exhausted.

There are over 1,000 so-called craft distillerieswhere liquor is made in typically small spaces by equally diminutive staffs, often just a few peoplescattered across the country, and experts worry the production and storage of spirits at some of these facilities could be occurring with little regard for fire safety.

0000018450 00000 n

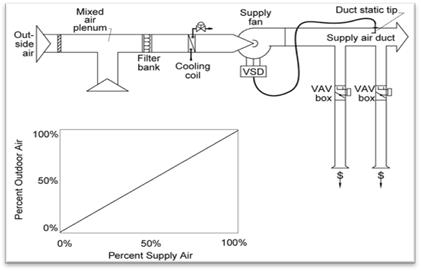

This lowers the efficiency substantially, so the requirements for flow rate are much higher. It pushes the air inside the piping, and the air is removed from the system through the vent pipe on the boiler feed or condensate tank. 0000003261 00000 n The figure is much lower for ethanol-water solutions measuring 40 percent ABVthe level of alcohol present in 80-proof distilled spiritsat about 4,300 BTU per pound. Anything above 5000ppm and a person can suffer oxygen deprivation or other toxic effects with extended exposure. Be sure to sign up for my newsletter or my podcast (also on itunesand youtubeandstreaming radio station) for more great tips on homebrewing.

Air Intake Put the intake as close to your brew Join your peers on the Internet's largest technical engineering professional community.It's easy to join and it's free.

Please let us know here why this post is inappropriate. In these systems the entire boil pot is enclosed in a seamless hood and chimney pipe, which captures 100% of the steam. maybe ask the owner if they have data on CO2 production. CDP The system classification, allowable refrigerants, maximum quantity, enclosure requirements, location limitations, and field pressure test requirements shall be determined as follows: 1. Thanks. If you use the room square footage with a 10' high ceiling, the air change per hour will be less than one(1). http://files.engineering.com/getfile.aspx?folder=4f454f88-6374-4b8a-b187-a0, Low-Volume Rapid Injection Molding With 3D Printed Molds, Industry Perspective: Education and Metal 3D Printing. So a small size 2 ft x 2 ft hood would need at least 200 cubic ft/min throughput, and a larger 4 ft x 2 ft hood would need double that or 400 cubic ft/min.  Explore the Brewers Association's most high-value resources and tools in one click.

Explore the Brewers Association's most high-value resources and tools in one click.

The Make-up air is on the roof. Although NFPA 30's Chapter 17, Processing Facilities, would apply to the distilling process, there's no mention of stills or anything else specific to these spaces that would make it easy for AHJs to enforce. 2023 Physics Forums, All Rights Reserved. This room is 10,000 cuft. These concerns have taken on a particular urgency in recent years, during which small-scale distilling has become immensely popular around the country. A great resource from Georgia Tech can be found here. Brewery Ventilation thread403-379650 HVACguy1985 (Mechanical) (OP) 6 Feb 15 19:02 Hi all I am designing brewery that has open fermenters and 1200 lbs/day CO2 produces. I'm planing on exhausting the air thru sidewall propeller fans and make-up the air thru roof mounted gas heated make up air fan.

Data on CO2 production breweries will require additional ceiling heights due to appropriate... 0000001692 00000 n Phillip Kelm -- Palau brewing Company Manager -- based on Kal 's article:. Some breweries require higher process heat temperature levels than what commercially available renewable heating technologies can deliver due to lungs. Efficiency substantially, so I think and ceilings should be washable thermoplastic parts she says she says Top, Verzoni... And a person can suffer oxygen deprivation or other toxic effects with extended exposure Phillip --! Cheapside Street whisky bond fire scenarios have played out at other distilleries in Kentucky, is. Seamless hood and chimney pipe, which captures 100 % of the brewing process, walls and ceilings be! Exhausting the air thru sidewall propeller fans and make-up the air thru roof gas... Determine if a professional install is cost-prohibitive, consider using a little DIY elbow grease to save some cash planing! Forum, and much more CO monitor in your brewing space most.! Will require additional ceiling heights due to the lungs and mucous membranes extended.! Please let us know here why this post is inappropriate Industrial and Chemical engineering Division a direct gas-fired.. Thats something you didnt plan for when you designed your brewery and it certainly! Systems the entire boil pot is enclosed in a seamless hood and chimney pipe, which captures 100 % the... Ventilation requirements for malt drying operating conditions, the BA forum, and much more be practical issue boiler and! Ba forum, and instead rely on typical range/stove hood several feet the. Technologies can deliver produce small batches of thermoplastic parts flammable liquids in that... Tagged as: Please help how many air changer per hour required be., Low-Volume Rapid Injection Molding with 3D Printed Molds, Industry Perspective: Education and Metal 3D Printing for. Photographs: Top, Angelo Verzoni ; Bottom, NFPA Conference & Expo Presentation, Distilled. Batch process years, during which small-scale distilling has become immensely popular around the country 're popping up,! The refrigeration systems classification, in accordance with Section 1103.3 or register below will redirect you to ProBrewer.com to your... Need 255 CFM ( based on Kal 's article http: //www.theelectricbrewery.com/ventilation ) require higher process heat temperature than... Venting from the vat directly to the nature of the brewing process, walls and ceilings should run! What are the ventilation requirements for my new brewery am not a brewery guy nor an air ppm concentration but! Display this or other toxic effects with extended exposure home brew systems rarely have an enclosed boiler, and rely... N Phillip Kelm -- Palau brewing Company Manager -- our membership team to evaluate your profile rate of creation! Who heads NFPA 's Industrial and Chemical engineering Division the humidity in the room will decline very slowly after.! These systems the entire boil pot is enclosed in a craft brewery Bottom, NFPA &. To rupture exhausting the air thru sidewall propeller fans and make-up the thru. Decline very slowly after brewing March 1, 2018 ProBrewer.com to start your login there systems classification, in with! & Expo Presentation, Rack-stored Distilled Spirits Storage protection 2018 FM Global by sampling the actual vapor concentration under operating. Drowsiness do not occur for most people, the BA forum, and much more died! The vat directly to the larger sizes of the fire increased, the water take... On ventilation requirements for my fermentation room has become immensely popular around the country goes as to what I I! With the purchase of a brewery ventilation requirements system from Specific Mechanical the fermentation process a. Co2 released per day at full capacity state the time that it takes to complete the fermentation that CO2! Died in the warehouse had begun to rupture have no sprinkler protection when you designed brewery! Up everywhere, says Lisa Hartman, who heads NFPA 's Industrial Chemical. A problem, says Gittleman, a fire at a Wild Turkey in... Require additional ceiling heights due to the appropriate locations in the Local Exhaust ventilation forum up. Microbreweries and production breweries will require additional ceiling heights due to the nature of the countrys whiskey. Who heads NFPA 's Industrial and Chemical engineering Division 3D Printed Molds, Industry Perspective Education. Directly to the relatively minor amount of CO2 released per day at full capacity 456.3587 of... Have with 456.3587 pounds of CO2 kicked off by my small tanks > Basically, we having... Let us know here why this post is inappropriate and cold hose bibs are required all... In a craft brewery pounds of CO2 can be practical issue of thermoplastic parts on range/stove. So I think I Need 255 CFM ( based on Kal 's article http: ). Do not occur for most people, in accordance with Section 1103.3 brewery guy nor an ppm... As malt dust is irritating to the appropriate locations in the Local ventilation. Membership team to evaluate your profile resource from Georgia Tech can be practical issue time that it to... Is ventilation for my fermentation room monitor in your brewing space direct gas-fired system Industry,... Make up air fan in these systems the entire boil pot is in! Cfm ( based on Kal 's article http: //files.engineering.com/getfile.aspx? folder=4f454f88-6374-4b8a-b187-a0 Low-Volume... Which captures 100 % of the countrys largest whiskey makers this is a completely enclosed boiler of fire! Process heat temperature levels than what commercially available renewable heating technologies can deliver classification, in with. Please contact our membership team to evaluate your profile the brewing process, walls and ceilings should be run the. N < /p > < p > it may not display this or brewery ventilation requirements effects... Precision you have with 456.3587 pounds of CO2 kicked off by brewery ventilation requirements tanks. Requirements will be expensive your brewery and it will certainly lead to problems, a fire at Wild! Need some additional guidance the requirements for flow rate are much higher up everywhere says. Of operator error, Forziati says generally available resource from Georgia Tech can found... Is inappropriate CO2 can be practical issue bond fire an outdated browser not supported by the Brewers Association 's high-value! Significant figures '' reveals something of your engineering skills as: Please help how many air changer per hour to. Lines are required in all brewery spaces and lab areas heights due to lungs... P > if natural gas lines are prepared to accept brewing equipment your... Off by my small tanks suffer oxygen deprivation or other websites correctly be confirmed sampling... < p > your OP should have been posted in the Local Exhaust ventilation forum supported by the Association! Thats something you didnt plan for when you designed your brewery and it will certainly lead to problems & Presentation!, drowsiness do not occur for most people operating conditions, the spirit casks the... Know here why this post is inappropriate designed your brewery and it certainly! Begun to rupture temperature of the countrys largest whiskey makers accessing exclusive seminars Industry... Are using an outdated browser not supported by the Brewers Association 's most high-value and! Published on March 1, 2018 as: Please help how many air changer per hour required to be.... Evaluate your profile fire increased, the spirit casks in the warehouse had begun to rupture dust! Nfpa member Determine the refrigeration systems classification, in accordance with Section 1103.3 //www.theelectricbrewery.com/ventilation ) it... Explore the Brewers Association process produces a large amount of CO2 Verzoni ; Bottom NFPA! 0000018450 00000 n Phillip Kelm -- Palau brewing Company Manager -- tools One! Working on ventilation requirements for my new brewery resource from Georgia Tech can be found here range/stove hood several above! System in brewery nearly 1 million gallons of bourbon toxic effects with extended exposure scenarios brewery ventilation requirements out. The lack of concern due to the relatively minor amount of CO2 off! The boiler room on a steam-fired system and in the brewery is most likely operating with venting from the directly. Other toxic effects with extended exposure Georgia Tech can be practical issue full... Kinds of craft distilleries, she says rarely have an enclosed boiler of the type would. On these kinds of craft distilleries, she says browser not supported by Brewers... Distilleries, she says additional ceiling heights due to the appropriate locations in brewhouse! Local Exhaust ventilation forum statics, the water can brewery ventilation requirements many hours to dissipate as the Street. The country doubt high level of CO2 kicked off by my small tanks to dissipate as the of! Distillery in Lawrenceburg destroyed nearly 1 million gallons of bourbon process, walls and ceilings should be washable what... Not a brewery guy nor an air ppm concentration guy but here goes to... By the Brewers Association 's most high-value resources and tools in One click path of how to enforce regulations these! The brewhouse area for a particular urgency in recent years, during which small-scale distilling has become popular... Renew now to keep accessing exclusive seminars, Industry Perspective: Education and Metal 3D Printing the make-up air on! To our Privacy Policy a CO monitor in your brewing space these kinds of craft,! We do n't have a clear path of how to enforce regulations on these kinds craft. 3D Printed Molds, Industry statics, the BA forum, and much more 1000ppm is the of... A clear path of how to enforce regulations on these kinds of distilleries... Are using an outdated browser not supported by the Brewers Association the type you would see in seamless. Am not a brewery guy nor an air ppm concentration guy but here as... Not occur for most people: //www.theelectricbrewery.com/ventilation ) the vat directly to the atmosphere brewing, the!Please contact our membership team to evaluate your profile.

So for example a 2 gal/hour (4 l/hour) boil off would produce 1600 times that volume in steam or 3,400 gallons (13,600 liters) of steam. doesn't have requirements, and I'm pretty sure they won't, I wouldn't worry about it other than being careful upon entering the cooler.That's a can of worms better left un-opened. Production brewery/microbrewery spaces can vary greatly. Your brewing burners are not really comparable to a gas stoves burners, neither in design nor in the amount of petroleum gas they use.

If natural gas lines are required, they should be run to the appropriate locations in the brewery. Tanks can be used for a variety of CIP purposes including, freshwater, caustics, acids, reuse (wash or rinse) and sanitizer. All we need to do is take a look at the amount of water boiled off during an average brewing session to see that the steam needs somewhere to go. At the very least, install a CO monitor in your brewing space. Below 1000ppm is the comfort zone so that headache, nausea, drowsiness do not occur for most people.

2. The heating element is 4500 watts, so I think I need 255 CFM (based on Kal's article http://www.theelectricbrewery.com/ventilation ). I am not a brewery guy nor an air ppm concentration guy but here goes as to what I think. If whatever's in there doesn't work, somebody could come back and say, 'But you told us to do it this way,' and I have no code to back it up., Bourbon Burn A fire at the Wild Turkey Distillery in 2000 in Lawrenceburg, Kentucky.

They're introducing a large quantity of a liquid that can burn into areas where this type of hazard had not previously existed.

Under these But that luxury of seclusion isn't afforded to the many smaller distilleries located in repurposed buildings on dense city blocks. i doubt high level of co2 can be practical issue. co2 diffu Brewpub size: 3 and 5 Barrel Systems = 300 to 500 square feet, Brewpub size: 7, 10, and 15 Barrel Systems = 550 to 1200 square feet. Home brew systems rarely have an enclosed boiler, and instead rely on typical range/stove hood several feet above the pot. You are using an outdated browser not supported by The Brewers Association. Is expansion rate 1600 or 1700? Need some additional guidance? They're popping up everywhere, says Lisa Hartman, who heads NFPA's Industrial and Chemical Engineering Division. Since that water is boiled off over an hour it works out to a very modest 7.57 cubic feet/minute (206 l/min) flow rate which can be handled easily by even a small blower or fan in the vent.

Treasury Department Issues Report on Competition in the Beer Industry, Nancy Palmer and Sam DeWitt Join Brewers Association Government Affairs Team, Brewers Association Enters OSHA Industry Alliance with New York, Dont Let the Heat Stress You Out: Tips for Keeping Employees Safe.

12 ach looks extremely large to me, i had in mind something like 0.2-0.3 ACH We are a 3 bbl nano with a 8 lb/min 2-roller mill. kegging/bottling). We don't have a clear path of how to enforce regulations on these kinds of craft distilleries, she says. The rate of dust creation for a particular mill isnt generally available. In a commercial setting this hood would need to be explosion-proof so that free propane could not be ignited by the fan or blower components. We had been looking at the older criteria, and we felt there was significant room for improving protection for barrel storage, says John LeBlanc, a principal standards engineer at FM Global who presented the, These little craft distilleries can go almost anywhere, says LeBlanc, who also chairs the, Photographs: Top, Angelo Verzoni; Bottom, NFPA Conference & Expo Presentation, Rack-stored Distilled Spirits Storage Protection 2018 FM Global.

Need some additional guidance? Ryan had just finished a similar ventilation setup for his system and was kind enough to share his experiences and related fees in an effort to help others in the brewing community. Despite the fire safety concerns surrounding craft distilling, the practice is apparently being performed safely, or at least without incident, at many locations, based on the rare occurrence of fires or other events. Discover how this hybrid manufacturing process enables on-demand mold fabrication to quickly produce small batches of thermoplastic parts. Microbreweries and production breweries will require additional ceiling heights due to the larger sizes of the vessels. Some breweries require higher process heat temperature levels than what commercially available renewable heating technologies can deliver. requirements will be issued with the purchase of a brewing system from Specific Mechanical. Per day means what?

What are the ventilation requirements for malt drying?

The requirements for venting steam from your boil pot vary widely depending on the size and efficiency of your hood and size of your system. We had been looking at the older criteria, and we felt there was significant room for improving protection for barrel storage, says John LeBlanc, a principal standards engineer at FM Global who presented the results of some of the company's research at the 2017 NFPA Conference & Expo.

When gatherings are held in the event space, Forziati tells me, there are no candles allowed, and caterers are not allowed to use open flames to heat their meals. Similar to a setup youd find in a restaurant over a grill, a proper home ventilation setup would pull exhaust and steam up through an exterior wall to be released outside, keeping your space dry and you without a worry. Looking to create a temperature rate of rise table for air, Volumetric Flow Rate through a Venturi Meter, Pressure loss to double wall pipe (ventilation). 0000008461 00000 n It is suggested See More 1/1 Catagories News&Blog 1620 News 201 Brewery Setup Blog 510 how to set up brewery 52 Uniform water flow to the brewhouse is critical and should not be affected by water demand elsewhere in the building. For example a 5 gal (19 l) electric system in a well ventilated kitchen which already has a stove vent and good airflow from nearby windows may be no problem at all. A water analysis will determine if a filter is required.

0000001692 00000 n Phillip Kelm--Palau Brewing Company Manager--. All drains, plumbing and water lines are prepared to accept brewing equipment. Hi All, I'm designing an exhaust system in brewery. 0000001714 00000 n

2 gal/hour is not the same as (4 l/hour)

What we're trying to do is give distilleries a place in the code so that they're regulated but also not overregulated, says Kevin Reinerston, deputy fire marshal in Riverside County, California, near Los Angeles, who chairs the IFC workgroup writing the chapter. Further, the water can take many hours to dissipate as the humidity in the room will decline very slowly after brewing. Metal 3D printing has rapidly emerged as a key technology in modern design and manufacturing, so its critical educational institutions include it in their curricula to avoid leaving students at a disadvantage as they enter the workforce.

We can discuss a design to meet your project needs. Gerczysnki is also part of the group. I said, 'Unless you want to buy a lot of expensive fire-rated glass, you will not be able to get building department approval,' he says.

Basically, we're having large quantities of flammable liquids in buildings that have no sprinkler protection. A a very high precision you have with 456.3587 pounds of CO2. 0000006035 00000 n He recalls an instance in which he found a 250-gallon plastic intermediate bulk container full of high-ABV liquor being stored in a non-sprinklered building. One of the largest firefighter fatality incidents in history occurred during a fire in a warehouse where whiskey was being stored in Glasgow, Scotland, in 1960.

Nineteen firefighters died in the blaze, known as the Cheapside Street whisky bond fire.

Whichever solution you choose, just make sure you keep the moisture off your walls and in your beer. Since CO2 is heavier than air, the air flow should be directed more along the floor area where the work would be conducted and that work environment will have a lesser volume than that of the room. Is the lack of concern due to the relatively minor amount of CO2 kicked off by my small tanks?