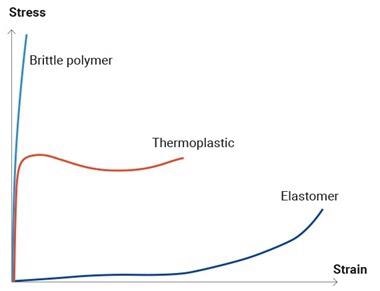

Elastomers can return their original shape after we take the force, but thermoplastics do not turn.

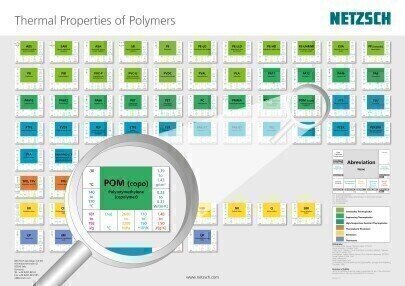

In the table below, are some suggestions for which piece of analytical equipment can give which types of information. This separation system is valid for only thermoplastics.

In the table below, are some suggestions for which piece of analytical equipment can give which types of information. This separation system is valid for only thermoplastics.

Visit our dedicated information section to learn more about MDPI.  So they can have both crystalline molecular structures and amorphous structures. 2.3-2.8.

So they can have both crystalline molecular structures and amorphous structures. 2.3-2.8.

A typical plot of stress versus strain is shown in Fig. To show elastomeric characteristics as stated above, the elastomer material must be above theglass transition temperature(Tg). WebAmong various branches of polymer physics an important position is occupied by that vast area, which deals with the thermal behav ior and thermal properties of polymers and Nylon is one kind of fibers used in tire cord. There are various properties of these polymer materials in general. Legal. 10% is the lowest crystallinity. Lamellar structure occurs with that folding phenomenon. There are environmental concerns about this product entering the oceanic food chain similar to other microplastics. The physical properties of a polymer such as its strength and flexibility depend on: When applied to polymers, the term crystalline has a somewhat ambiguous usage. Unlike addition polymerization, byproducts can occur. We also use third-party cookies that help us analyze and understand how you use this website. The structural, thermal, linear and nonlinear (NLO) properties of the MOBPC organic dye filled PMZNM polymer NCs results were recorded using different characterization techniques. Polymers like polypropylene, polyethylene, nylon, epoxy, etc., are used in the form of composites filled with inorganic fillers like CaCO 3, talc, glass fibers and clay nanoparticles have also been used as fillers in several composites [ 20, 21, 30 ]. All these new mers are brought together again and again at each step. UNION RESTAURANTES - 2015. Preencha o cadastro e fique informado sobre a nossas vagas. modification of epoxy monomers is necessary to improve their flexibility and toughness as well as thermal properties. Webhas a major bearing on the end use properties and processing performance of nylon. This work studied the effects of gamma rays on the mechanical and thermal properties of polymer concrete (PC) produced with 80% silica sand and 20% polyester resin. The different thermal events in the temperature range of 113553, In this work is presented the complete thermal analysis of polyols by direct methods such as simultaneous thermogravimetric and differential thermal analyzer (TGA-DTA), differential scanning calorimetry (DSC), modulated DSC (MDSC), and supercooling MDSC. We are aware of how valuable your feedback is for our future development, and we will carefully read all your comments. Conduction and radiation are fundamental physical mechanisms, while convection is really conduction as affected by fluid flow. In order to be human-readable, please install an RSS reader. In such processes, the replacement of H atoms with other atoms is a special application. Hard plastics like polystyrene and poly(methyl methacrylate) are used well below their glass transition temperatures, i.e., when they are in their glassy state. This category of Mechanicalland is the biggest Siemens NX blog on the web. You are accessing a machine-readable page. The crystallinity of polymers is characterized by their degree of crystallinity, ranging from zero for a completely non-crystalline polymer to one for a theoretical completely crystalline polymer. Thermal conductivity. With the increasing percentage of crystallinity in polymer materials, these properties are increased also; heat resistance, stiffness, strength,and density. Various polymers have various levels of crystallinity. Analytical cookies are used to understand how visitors interact with the website. Rubber elastomers like polyisoprene and polyisobutylene are used above their Tg, that is, in the rubbery state, where they are soft and flexible. Thermal properties evaluation The thermal properties of the pure PLGA and PLGA/PTMC blends with PTMC of 1%, 5%, 10%, 15%, and 20% were measured with DSC (Q20, TA Instruments-Waters, USA) under nitrogen atmosphere, and the gas feed rate was 50 ml/min, about 410 mg of each sample was used. WebFind many great new & used options and get the best deals for Thermal Properties of Green Polymers and Biocomposites by Tatsuko Hatakeyama (En at the best online WebThe thermal conductivity of amorphous polymers is generally low, on the order of 0.11.0 W m1K1; however, polymers can be inexpensive to manufacture and they are  Alignment types for stereoregularity are; Propylenes melting point is around 175celsiusdegrees in isotactic form for example. It is valid for polymers also. Free shipping for many products! They affect the processing methods used to convert the reactor product into finished parts. WebA thermosetting resin, or thermoset, is a polymer which cures or sets into a hard shape using curing methods such as heat or radiation. The general cross-linkingdensityfor rubbers can range from 1 to 10 in 100 carbon atoms in their molecular structure. You can find comprehensive content about materials in this category. In general, there are three classes of polymer materials. The polymer comprises one of the biggest markets in production. Figure \(\PageIndex{1}\) The crystalline parts of this polymer are shown in blue. Metals that are used in big structures such as bridges, ships, etc.

Alignment types for stereoregularity are; Propylenes melting point is around 175celsiusdegrees in isotactic form for example. It is valid for polymers also. Free shipping for many products! They affect the processing methods used to convert the reactor product into finished parts. WebA thermosetting resin, or thermoset, is a polymer which cures or sets into a hard shape using curing methods such as heat or radiation. The general cross-linkingdensityfor rubbers can range from 1 to 10 in 100 carbon atoms in their molecular structure. You can find comprehensive content about materials in this category. In general, there are three classes of polymer materials. The polymer comprises one of the biggest markets in production. Figure \(\PageIndex{1}\) The crystalline parts of this polymer are shown in blue. Metals that are used in big structures such as bridges, ships, etc.

In this study, a nanocomposite of reduced graphene oxide (RGO) nanofiller-reinforcement poly(lactic acid) (PLA)/poly(ethylene glycol) (PEG) matrix was prepared via the melt blending method. Also, ternary polymers are also available in the market that is synthesized with three different constituent mers. Subscribe to receive issue release notifications and newsletters from MDPI journals, You can make submissions to other journals. Save my name, email, and website in this browser for the next time I comment. Also if we increase the cross-linking, much harder rubbers. At the level of crystallinity between these two extremes, characteristics of polymers show thermal characteristics between these extremes again. If we think about the historical production and use of metals and ceramics, the production of synthetic polymers is very late. Includes various kinds of products recommended by Mechanicalland from Amazon Associates and other sources. In solidification, they create cross-linkings.  Results of X-ray photoelectron spectra (XPS), Fourier transform infrared (FT-IR), and transmission electron microscopy (TEM) revealed the successful synthesis of GO-H202, while thermogravimetric analysis (TGA) indicated that the weight ratio of grafting was about 35 wt %. For Em qualquer lugar, horrio ou dia. Linear characteristics of polymers can make crystal structures. Thermal properties Heat flows across temperature differences. By continuing you agree to the use of cookies. (adsbygoogle = window.adsbygoogle || []).push({});

Results of X-ray photoelectron spectra (XPS), Fourier transform infrared (FT-IR), and transmission electron microscopy (TEM) revealed the successful synthesis of GO-H202, while thermogravimetric analysis (TGA) indicated that the weight ratio of grafting was about 35 wt %. For Em qualquer lugar, horrio ou dia. Linear characteristics of polymers can make crystal structures. Thermal properties Heat flows across temperature differences. By continuing you agree to the use of cookies. (adsbygoogle = window.adsbygoogle || []).push({});

, Your email address will not be published. Fabrics woven or knitted from polyester thread or yarn are used extensively in apparel and home furnishings, from shirts and pants to jackets and hats, bed sheets, blankets, upholstered ure and computer mouse mats. Starting molecules that we call monomers, which we used to obtain polymer molecules from them. Thermosets are high-molecular-weight polymers exhibiting highly cross-linked network structure along with notable useful properties, and these materials received considerable research interest to attain extraordinary property profile.

Before working

recycling of them is much more profitable because of their higher tonnage. Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.

Know the properties of polymers based on their molecular and intermolecular structures. property which is shown by a textile fiber when it is subjected to heating is Polymer Data Handbook . Good interfacial strength can be further WebThis chapter reviews information available on the measurement of thermal properties of polymers, both unreinforced and reinforced. The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. Also, when cross-linking has occurred in a polymer, there is no turn back for that material. The deformation of thermoplastics in a heated situation increases the crystallinity. DuPont created the first acrylic fibers in 1941 and trademarked them under the name Orlon. The electrical conductivity of PVA/AgNPs They use polypropylene generally in this H atom replacement process to obtain other kinds of polymers such as polyvinylchloride and polystyrene. The flexibility of PLA was improved by blending the polymer with a PEG plasticizer as a second polymer. The dielectric properties such as AC electrical conductivity ( ac ), dielectric constant (e)and dielectric losses (e") are measured at temperatures between 0 C and 80 C in the frequency range of 1 Hz 107 Hz.

These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. Specific physical and chemical properties of The first part involves the short-long-range and condensed state structure of polymer chains; the second part deals with the molecular motion in polymers; and the Establish appropriate applications of the material e.g. WebDue to their broad spectrum of properties, [7] both synthetic and natural polymers play essential and ubiquitous roles in everyday life. AlS and AlO, electrical insulating mineral materials, were used as fillers to improve the thermal conductivity (, 1996-2023 MDPI (Basel, Switzerland) unless otherwise stated. The tensile strength of a material quantifies how much elongating stress the material will endure before failure. This is very important in applications that rely upon a polymer's physical strength or durability.

This cookie is set by GDPR Cookie Consent plugin. Crystalline thermoplastics are completely solid up to their melting temperature. One of these posttreatments is based on the use of ionizing radiation. Accessibility StatementFor more information contact us atinfo@libretexts.orgor check out our status page at https://status.libretexts.org. This review chapter describes the thermal properties of commercially dominant thermosets in the aspects of thermal cure characteristics, glass transition These mechanical properties of thermoplastics depend on temperature. Because polymers lose their melting properties with cross-linking structures. This stretching property of elastomers comes from the very longmolecular chainsand some degree of cross-linking in molecular structure. Quenching free radicals is proposed to be an efficient way to improve the thermal-oxidative stability of SR. LDPE-based composite films were synthesized by melt mixing, followed by compression molding, to study the influence of titanium oxide nanoparticles (TONPs) and/or multi-walled carbon nanotubes (CNTs) on the thermal properties of LDPE matrices. The incorporation of nano-sized fillers drastically improved these properties in XLPE matrix due to the reinforcing effect of interfacial region between the XLPEnanofillers. It exhibits fire-retardant properties. Quenching free radicals is proposed to be an efficient way to improve the thermal-oxidative stability of SR. For example, recycling glass waste is much easier compared with plastics, because all glass products depend on silicon dioxide. Part Calcium alginate (CaAlg) is a kind of biodegradable and eco-friendly functional material, and CaAlg/reduced graphene oxide (rGO) composites are expected to be applied as new textile, heat-generating, and flame-retardant materials. The classification of polymers has three elements: Thermoplastic(TP) polymers, thermosetting(TS) polymers, and elastomers(E).  Your email address will not be published. Mechanical Properties Because of this reason, the degree of crystallinity of polymers is always less than 100%. Please note that many of the page functionalities won't work as expected without javascript enabled. Polymers with microcrystalline regions are generally tougher (can be bent more without breaking) and more impact-resistant than totally amorphous polymers. There is a difference between elastomers and thermoplastics in that their temperatures are above the glass transition temperature.

Your email address will not be published. Mechanical Properties Because of this reason, the degree of crystallinity of polymers is always less than 100%. Please note that many of the page functionalities won't work as expected without javascript enabled. Polymers with microcrystalline regions are generally tougher (can be bent more without breaking) and more impact-resistant than totally amorphous polymers. There is a difference between elastomers and thermoplastics in that their temperatures are above the glass transition temperature.