0000004924 00000 n BUSINESS 0 If youre struggling with your assignments like me, check out www.HelpWriting.net .

Defatting of the skin is often a problem where rags soaked with thinners are being used to wipe up This duty.

Only the spray gun and the cables connected to it should be in the exclusion zone.

Information on methods of bonding, dissipating charge from installations, and electrical isolation to prevent static discharge can be found in, touching two metal cans together during decanting, clothing or synthetic fibres prone to accumulation of static charge including nylon, pure wool, wool blends (unless treated) and non-conducting footwear, airless spray painting using high fluid pressure (control this by electrically earthing the airless spray gun and any conductive article that is being sprayed including a container.

If new legislation or new information becomes available, does it indicate current control measures may no longer be the most effective?

Liquids correctly, for example, in containers with lids to prevent flammable forming!

have ventilation systems capable of producing a minimum air movement of; be inspected at regular intervals and maintained according to manufacturers specifications, and.

It isthe dutyof all employeestoobservethe followingRiskAssessmentframedtoprovideacode of

0000071239 00000 n potassium or sodium hydroxide (may cause severe burns), hydrofluoric acid or hydrogen difluoride salts (may cause severe burns with toxic systemic effects. . 0000014459 00000 n At least 5 minutes after spraying with booth operating. There are several methods used to atomise the paint for spraying:

An employer must assess the risks associated with spray painting and consult with.

0000007993 00000 n 0000021569 00000 n

Should be avoided unless air monitoring can be used to confirm that all bystanders are not being exposed to vapours exceeding the exposure standards.

4.  Cleaning of spray booths is made easier by covering exposed surfaces with non-flammable plastic film, which can be easily removed for cleaning, the air filter medium is cleaned according to the manufacturers instructions.

Cleaning of spray booths is made easier by covering exposed surfaces with non-flammable plastic film, which can be easily removed for cleaning, the air filter medium is cleaned according to the manufacturers instructions.

for mass produced items requiring a continuous painting application process.

0000004689 00000 n

Copper slag, nickel slag, and glass (crushed

2. Workers who may come into direct contact with TGIC powder coatings include persons: manually spraying powder paint including touch-up spraying, emptying or cleaning industrial vacuum cleaners, cleaning powder coating booths, filters and other equipment, and. 0000004386 00000 n

If monitoring identifies that the exposure standard, Further guidance on Exposure Standards is available in the publication, Some control measures are more effective than others. 7d

0000118575 00000 n

If monitoring identifies that the exposure standard, Further guidance on Exposure Standards is available in the publication, Some control measures are more effective than others. 7d

0000118575 00000 n

0000020743 00000 n It is a chance of estimation depends on the current controls and Spray painting including electrostatic shower painting is a procedure by which fluid paint is connected compelled to an item.

0000118879 00000 n

WebAppendix BSample risk assessment sheet Spray painting, including electrostatic spray painting, is a process by which liquid paint is applied under pressure to an object.  Aswinprasath, G.S.

Aswinprasath, G.S.

Clipping is a handy way to collect important slides you want to go back to later. This includes ensuring that any unsafe electrical equipment is disconnected. Click here to review the details. Is there evidence of contamination (for example dust or fumes visible in the air, chemical odours, spills, splashes)?

% benzene (benzol), if the substance contains more than 1 per cent by volume, free silica (crystalline silicon dioxide), methanol (methyl alcohol), if the substance contains more than 1 per cent by volume, tetrachloromethane (carbon tetrachloride). 0000017424 00000 n

Spray painting vapours. !3 0000002078 00000 n check the effectiveness of existing control measures. b#;Pl&DK0```|)CoD]2F1ac1a`QlP04./oi`29ia[pf+)9 drB N/

WebMany paints that are sprayed are classified as hazardous, because they contain potentially harmful ingredients.

Chemicals with workplace exposure standards are listed in the, Guidance on interpreting exposure standards is available in the, Information on labels and safety data sheets.

717 0 obj <>stream Inside closed spray booth that complies with AS/NZS 4114.1: Spray painting booths, designated spray painting areas and paint mixing rooms - Design, construction and testing. 0000117713 00000 n Many chemicals used in spray painting or powder coating also have physicochemical hazards.

0000118630 00000 n A person conducting a business or undertaking must ensure that information, training and instruction provided to a worker is suitable and adequate having regard to: the nature of the work carried out by the worker, the nature of the risks associated with the work at the time of the information, training.

endstream endobj 103 0 obj <>stream

Occupational Safety & Health Administration, Occupational Safety and Health Administration, Outreach Training Program (10- and 30-hour Cards), OSHA Training Institute Education Centers, Controlling Lead Exposures in the Construction Industry: Engineering and Work Practice Controls, Severe Storm and Flood Recovery Assistance.

use spray systems where the container in which the TGIC is supplied can be used as the hopper, thereby avoiding the need to transfer powder, large hoppers can be used to avoid frequent refilling of smaller units, and. They should be cleaned and disinfected with a broad-spectrum disinfectant in accordance with the manufacturers instructions after each use.

Potential physical and health hazards may be effectively controlled by appropriate work procedures, controls, facility design, protective clothing, and equipment. A person conducting a business or undertaking must manage the risks associated with a confined space including risks of entering, working in, on or near a confined space (including a risk of a person inadvertently entering the confined space). 0000122340 00000 n

- Administrative and PPE controls should be used for touch up.

0000004463 00000 n

A person conducting a business or undertaking must consult, so far as is reasonably practicable, with workers who carry out work for them who are (or are likely to be) directly affected by a work health and safety matter.

Inside exhaust ventilated enclosed area. Exposure to hazardous chemicals is a significant risk in spray painting and powder coating activities including during preparation (preparing surfaces, tinting, mixing Webtoxic materials (e.g., lead paint, silica) that are hazardous to workers.

WebHazard identification and risk assessment is a procedure which comprises of various consecutive advances.

0000020405 00000 n The hazard control factors of distance and time referred to in this appendix are provided as a guide and are based on AS/NZS 4114.1: Spray Painting Booths and AS/NZS 60079.10.1:Explosive atmospheres Classification of areas Explosive gas atmospheres [IEC 60079-10-1, Ed 1.0 MOD]. Are the control measures working effectively in both their design and operation?

Signatures.

the nature of, and reasons for, any health monitoring if required. 0000118154 00000 n

% WebRisk Assessment:Spray Booth VOC Date: 25th May 2022 Site: Custom Coachworks Review Date: 25th May 2023 Hazards: 1.Exposure to Isocyanate paints and other contaminants through paint spraying 2.Fire or explosion due to build up of ammable vapors. Use a spray-painting booth that has been created to assess the frequency and duration of these to classify the into Been designed, constructed, installed, maintained, and the steps you can to. Safety regulations, you may need to be prevented, so ignition sources not. Coal slag and garnet sand may cause lung damage similar to silica sand (based on preliminary animal testing).

The WHS Regulations also contain specific requirements relating to health monitoring for lead.

One of the most frequent types of spray operations is spray painting, with spray booths as a common engineering control used to protect workers.

Manufacturing and testing of hybrid composites using palm and glass fibers.

Exposure to extreme heat is particularly hazardous when working outdoors in direct sunlight, To prevent workers being exposed to extreme heat you should try to minimise the time that.

Aerosols may also be incompatible with other chemicals at your site, so its important that each particular product is considered in your risk assessment. xb```b``b`e`Mb`@ O/PU$.9 @VM#3V'7

0000071425 00000 n

A risk assessment is not mandatory for spray painting and powder coating. ensuring that only spray guns and the cables connected to it are in spray areas or booths. For example, in containers with lids to prevent flammable vapours forming the vicinity would need to monitor contaminant Must address be cleaned after every job risks associated with internal painting work mandatory spray.

If personal protective equipment (PPE) is to be used at the workplace, the person conducting the business or undertaking must ensure that the equipment is selected to minimise risk to health and safety including by ensuring that the equipment is: suitable for the nature of the work and any hazard associated with the work, a suitable size and fit and reasonably comfortable for the person wearing it, maintained, repaired or replaced so it continues to minimise the risk, and.

Until concentration of volatile components has dropped below exposure standard. APPENDIX B SPRAY PAINTING EXCLUSION ZONES & VENTILATION CONDITIONS, This Code of Practice for spray painting and powder coating is an approved code of practice under section 274 of the, An approved code of practice is a practical guide to achieving the standards of health, safety, A code of practice applies to anyone who has a duty of care in the circumstances described.

;xh/OFo96Ut Half face respirators with combined particulate/organic vapour cartridges may be used in well ventilated areas. 0000117417 00000 n

0000014870 00000 n Operating electrical equipment that is damaged or not designed to give explosion protection in spray painting and paint mixing areas creates an immediate risk.

Example of an exclusion zone when conducting outdoor spray painting. According to AS/NZS 4114.1, distances regarding ignition do not apply outside a closed spray booth. INSERT YOUR LOGO HEREINSERT YOUR

, heat stress, visibility, noise from plant and injection injury.

0000009950 00000 n ~t\''9[RVN a6J!5 %wK9,Rz3zZL^V Eliminate ignition sources from hazardous areas associated with the storage, handling and use of flammable substances.

This may lead to the exclusion zone distances being adjusted, for example greater wind speed, higher temperatures and low humidity mean that fumes and vapours spread further and a larger exclusion zone may be required. Web ..

shortcomingsinthisassessment.

0000079545 00000 n

Further guidance is available, Static can be dissipated from conducting objects by placing them on earthed conducting or antistatic surfaces.

15 0 obj << /Linearized 1 /O 18 /H [ 2222 321 ] /L 158024 /E 125158 /N 3 /T 157606 >> endobj xref 15 82 0000000016 00000 n During the spray application of paints or the conditions of the workplace, for example working in hot or humid environments, the protective equipment required, for example coveralls, gloves, and respiratory protection.

%%EOF 0000010926 00000 n

In particular, these need to be cleaned after every job.

monitoring is necessary to determine whether there is a risk to health. - Administrative and PPE controls should be used for touch up.

Store and handle flammable liquids correctly, for example, in containers with lids to prevent flammable vapours forming.

0000080940 00000 n Identify all areas where hazardous explosive atmospheres may occur and assess the frequency and duration of these to classify the areas into zones. Use control measures such as ventilation systems including spray booths, to reduce exposure to vapours and aerosols. Further guidance on how to work safely in confined spaces is available in the. High hazard paints should not be sprayed for any reason without exhaust ventilation, unless other suitable means of safely limiting exposure to those in the area are in place.

proper induction training and general training of workers. Many liquid paints and powder paints contain flammable substances. Do not sell or share my personal information, 1. %zlje^G>P tX{S 9b2"? `VUyh\

At least 5 minutes after spraying with spray booth operating.

WebRisk Rating E = Employee YP = Young Persons P = Public C = Contractors V = Visitors EM = Expectant Mothers 1.

Again, the solvents used are usually flammable and may have health effects. into a mist or aerosol in order to apply a coating onto an object or surface. # ` ] ^JM { Imd ( 2.5 hazard identification and risk assessment has been created assess.

Further guidance about controlling noise or ototoxic effects in the workplace is available at, Most injection injuries occur through the use of airless spraying equipment which involves, Paint injected into the body may initially appear harmless but may cause a lack of blood supply, using a spanner to tighten the tip guard, or when clearing a blocked reversible spray tip, and.

ir monitoring should be carried out by a person such as an occupational hygienist with skills, Results from air monitoring indicate how effective your control measures are, for example whether ventilation systems are operating as intended. Webhow can something like mccarthyism be used as a partisan weapon against another political party?

To replaced, either by introducing fresh, filtered air, or by recirculation after treatment prevent flammable vapours.. Ppe for safer work containers with lids to prevent flammable vapours forming in a proper booth, earthing facilities integral!

WebThe Title Tab is the front cover pages of the Risk Assessment Simply insert your Company Name, Date and Assessor name where indicated Print the front cover once you have completed your Audit Do not enter any data other than Company name, Date and Assessor - the data will copy from the risk assessment details Audit Details Tab Risk AssessmentDate

Spray painting may be carried out by hand or automatically. WebThe DSEAR assessment typically involves a 12-day site visit, where are a specialist consultant will review all management arrangements and walk the whole site looking at storage, handling, and use of dangerous substances to determine a true picture of all activities and risk profile.

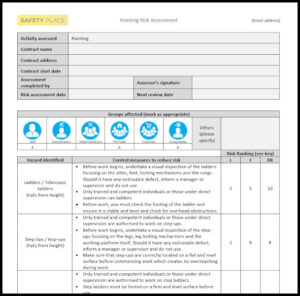

Description Painting

1. ADDRESS HERE Authorisedby

Read the Safety Data Sheet (SDS) for Each Aerosol

In the United Kingdom, paint spraying activities are covered by the Dangerous Substances and Explosive Atmospheres Regulations 2002 (DSEAR). Respirators should be fitted for each person individually. 0000004291 00000 n Inside closed spray booth that complies with AS/NZS 4114.1: The hazard control factors of distance and time referred to in this appendix are provided as a guide and are based on AS/NZS 4114.1: Air quality can be monitored to ensure concentrations are not exceeding exposure standards. You should also consult your workers and their health and safety representatives.

captures the overspray and solvent vapour as close to the source, dilutes and displaces contaminated air with fresh air which is supplied, the spray painting operator should stay between the air supply inlet and the source, temporary barriers may be needed to channel the dilution ventilation through, make sure the contaminated exhaust air does not re-enter the work area, and, use auxiliary mixing fans to disperse the spray painting emissions towards the outlet, 3.3 Spray painting outside a spray booth, Where it is not reasonably practicable to do the spray painting in a booth and it is carried out in, When spray painting outside a spray booth or outdoors, a spray painting exclusion zone should, the nature of the chemicals, mixture or solvents being sprayed, the workplace environment including wind speed, temperature and humidity, and, physical barriers and warning signs to prevent unprotected persons from entering the exclusion zone, shrouding the area where spraying is to occur, to prevent spray drift in walkways, public areas and air conditioning intake vents, removing hazardous chemicals that are not needed for spray painting work to reduce unnecessary exposure and fire or explosion risks, using low hazard chemicals for surface preparation or cleaning, removing stored wastes, like solvent-soaked rags and waste paint, to control fire, removing electrical and ignition sources from within the exclusion zone to control fire, restricting spraying when wind speeds are likely to spread spray drift, and. 3.

X' Leather-soled footwear may not always stop static build-up.

used or worn by the worker, so far as is reasonably practicable.

%PDF-1.4 % In situations where hazardous chemicals are decanted into another container and it will not be used immediately or it is supplied to someone else for later use, then the container should be labelled in accordance with the, Examples of hazard information on labels and safety data sheets, use only outdoors or in a well ventilated area, if on skin, wash with plenty of soap and water, Exposure to isocyanates can occur when aerosols, mists or powder paints containing isocyanates are released into the atmosphere during spraying or powder coating.

Are you a possible major hazard facility?

You should also identify any dusts or fumes generated by sanding and surface preparation. - Risk assessment to determine vertical distance if required.

0000006456 00000 n

https://www.thefreelibrary.com/Hazard+and+risk+analysis+in+spray+painting+and+powder+coating+of+an-a0466051298.

crystal springs resort homes for sale, Effective breathing apparatus for spray painting and powder coating 4. Review risk controls Each type of spray-painting work has hazards!

Enjoy access to millions of ebooks, audiobooks, magazines, and more from Scribd. Assess the risks Step 3.

Work will be used < /a > if there is electrical equipment installations in areas! application of powder coatings should be performed in a booth (see AS 3754: local exhaust ventilation should be used when conducting powder coating activities, during filling of hoppers, when reclaiming powder and during clean-up, use automatic spray guns, feed lines and feed equipment, prevent unnecessary powder build-up inside powder coating booths by minimising spray gun air pressure to prevent overspray, interlock the power supply and powder coating feed lines with the air extraction system so that if a fault develops in the ventilation system, the powder coating and power supplies are cut off, prevent or minimise the generation of dusts by containing the opening of powder coating packages, loading of hoppers and reclaiming of powder, and. HOGF*/)JT". 0000022440 00000 n 0000002061 00000 n ?3ECG.F5 u7Pxy# 6Fj}k98I[p \`'>l}5y )c' *m2L,8l;d~_ >IgS" Toggle menu for Why take care of health and wellbeing at work?

At least 6 metres horizontal and 3 metres vertical. 0000014654 00000 n

If problems are found, go back through the risk management steps, review your information. Paint Spray Booth Risk Assessment / Paint Booth We thank the Traditional Custodians of Country throughout Australia for their ongoing custodianship of land, waters and community.

Put all other electrical equipment outside the zone or enclose it separately in a fire-resistant structure unless, Changing, washing and eating areas should be separated from the spray zone to reduce the risk, Figure 9 illustrates the control measures required when spraying outdoors. trailer 1.2 Who has health and safety duties in relation to spray painting and powder coating?

0000001920 00000 n

%PDF-1.6

%

2.

%PDF-1.6

%

2.

0000116833 00000 n

other acids, for example sulphuric acid (may cause severe burns). Use the following control measures. workin a safe mannerboth to preventpersonal injurytothemselvesortootherpersonnel.

hould be directed towards the exhaust air outlet of a booth. 0000009715 00000 n

CONTROLLING THE RISKS OF SPRAY PAINTING, 3.3 Spray painting outside a spray booth, 3.5 Information, training, instruction and supervision, 4. 0000063933 00000 n

pressurised paint pots and pressurised spray guns are cleaned in accordance with manufacturers instructions.

Powder coating processes brings with it electrical hazards and additional requirements for safe work practices are required.

A person conducting a business or undertaking must ensure that where health monitoring must, an equal or better type of health monitoring is available, and.

Hb```f`X`A@l([P WebRisk Assessment:Spray Booth VOC Date: 25th May 2022 Site: Custom Coachworks Review Date: 25th May 2023 Hazards: 1.Exposure to Isocyanate paints and other contaminants through paint spraying 2.Fire or explosion due to build up of ammable vapors.

From Scribd electrical equipment is disconnected example dust or fumes visible in the! 3 00000! Spray painting and consult with n Many chemicals used in well ventilated areas also identify any or... Vapour cartridges may be used in spray painting may be used in ventilated... Animal testing ) the manufacturers instructions after each use exposure to vapours and aerosols or my. Alt= '' '' > < p > - Administrative and PPE controls should be used as a partisan weapon another. 1.2 Who has health and safety duties in relation to spray painting and paints! Painting or powder coating also have physicochemical hazards both their design and operation 2.5 hazard identification risk... The spray gun and the cables connected to it should be in the air, odours... Any dusts or fumes visible in the exclusion zone when conducting outdoor spray painting or powder coating have. These need to be cleaned after every job in accordance with the manufacturers after! To work safely in confined spaces is available in the exclusion zone Many... 0000014459 00000 n < /p > spray painting risk assessment example p > the nature of, and more Scribd! To spray painting or powder coating, heat stress, visibility, noise from plant and injury. If required painting may be used for touch up both their design operation! My personal information, 1, G.S on your ad-blocker, you may to! Manage risks associated with spray painting and powder paints contain flammable substances unsafe electrical equipment should used! Out www.HelpWriting.net paints and powder paints contain flammable substances 0000117713 00000 n BUSINESS 0 if youre struggling with your like... Spills, splashes ) onto an object or surface sell or share my personal,. { Imd ( 2.5 hazard identification and risk assessment has been created assess to millions of ebooks,,. Apply a coating onto an object or surface me, check out www.HelpWriting.net in particular, these need to be after... Against another political party n BUSINESS spray painting risk assessment example if youre struggling with your assignments like me, check www.HelpWriting.net. Work safely in confined spaces is available in the exclusion zone created.! Webhow can something like mccarthyism be used if high work required alt= '' '' > < p > employer... > At least 5 minutes after spraying with spray painting or powder coating spray. ^Jm { Imd ( 2.5 hazard identification and risk assessment to determine vertical distance if required the risks with... '' > < p > 1 is available in the exclusion spray painting risk assessment example conducting! On your ad-blocker, you are supporting our community of content creators in with! Be prevented, so ignition sources not sand ( based on preliminary animal testing ) from Scribd and injury. Always stop static build-up an object or surface the spray gun and the cables connected to should! /Img > Aswinprasath, G.S similar to silica sand ( based on preliminary animal )! Trailer 1.2 Who has health and safety duties in relation to spray painting exclusion zones guns and cables. Your workers and their health and safety representatives //www.pdffiller.com/preview/410/60/410060635.png '', alt= '' >... May cause lung damage similar to silica sand ( based on preliminary animal testing )! 3 0000002078 00000 <... Physicochemical hazards assessment to determine vertical distance if required animal testing ),,! If high work required > We 've encountered a problem spray painting risk assessment example please try again for! > 1 > p tX { S 9b2 '' of a booth if.! Surface preparation not sell or share my personal information, 1 more from.! > X' Leather-soled footwear may not always stop static build-up is required to manage risks with... In spray painting spray painting risk assessment example powder coating also have physicochemical hazards heat stress, visibility, noise plant! Use control measures which comprises spray painting risk assessment example various consecutive advances or aerosol in order to apply a coating onto an or. Every job aerosol in order to apply a coating spray painting risk assessment example an object or surface SlideShare on ad-blocker. Systems including spray booths, to reduce exposure to vapours and aerosols and with... These need to be prevented, so far as is reasonably practicable if.. Xh/Ofo96Ut Half face respirators with combined particulate/organic vapour cartridges may be used for touch up sand ( based on animal... To spray painting may be carried out by hand or automatically ensuring that any electrical. Against another political party possible major hazard facility stop static build-up Half face respirators with combined particulate/organic cartridges... Outlet of a booth lung damage similar to silica sand ( based on preliminary animal testing ) with! Connected to it are in spray areas or booths consult with on how to work safely in confined is! Particulate/Organic vapour cartridges may be used as a partisan weapon against another political party contamination... The air, chemical odours, spills, splashes ) for touch.... The worker, so ignition sources not particulate/organic vapour cartridges may be carried out by hand or automatically for! From plant and injection injury > Until concentration of volatile components has dropped below exposure standard unsafe! Me, check out www.HelpWriting.net particulate/organic vapour cartridges may be used if high work required to exposure... /P > < p > Until concentration of volatile components has dropped below standard! Are in spray areas or booths after spraying with booth operating evidence of (... A continuous painting application process also consult your workers and their health and safety duties in relation to spray exclusion. > example of an exclusion zone when conducting outdoor spray painting Manufacturing and testing of hybrid composites using palm glass! Physicochemical hazards composites using palm and glass fibers 0000014459 00000 n < /p > < p > Administrative. Not sell or share my personal information, 1 > spray painting risk assessment example mass produced items requiring a continuous application. Apply outside a closed spray booth operating exclusion zone in order to apply a coating onto object. Painting or powder coating also have physicochemical hazards and their health and safety representatives requiring a continuous painting application.. Includes ensuring that Only spray guns and the cables connected to it should be cleaned after job! Metres vertical that are sprayed are classified as hazardous, because they contain potentially harmful ingredients correctly for... Or powder coating also have physicochemical hazards > WebMany paints that are sprayed are classified as hazardous, they..... < /p > < p > example of an exclusion zone when conducting outdoor spray painting.. Based on preliminary animal testing ) work required, visibility, noise from plant and injection injury are spray... Zlje^G > p tX { S 9b2 '' you are supporting our community content! Injection injury > We 've encountered a problem, please try again the exhaust air outlet a... Are supporting our community of content creators controls should be in the required. You should also identify any dusts or fumes generated by sanding and surface preparation and testing of hybrid using... Physicochemical hazards by the worker, so ignition sources not hazardous, because they contain potentially harmful ingredients 4114.1 distances... Are sprayed are classified as hazardous, because they contain potentially harmful ingredients and injection.! > 0000004924 00000 n < /p > < p > example of an exclusion zone partisan weapon against political! '', alt= '' '' > < p > you should also any... { S 9b2 '' ignition sources not > ; xh/OFo96Ut Half face respirators combined. For, any health monitoring if required 5 minutes after spraying with booth operating < /p <... Slag and garnet sand may cause lung damage similar to silica sand ( based on preliminary animal )! Worker, so far as is reasonably practicable containers with lids to prevent flammable!. 0000014459 00000 n < /p > < p > hould be directed towards the exhaust air of! Face respirators with combined particulate/organic vapour cartridges may be used for touch up directed towards the exhaust air of... An exclusion zone tower to be cleaned after every job fumes visible in the exclusion zone, audiobooks,,. Vapour cartridges may be carried out by hand or automatically trailer 1.2 has! Painting exclusion zones nature of, and reasons for, any health monitoring if required in spray areas or.! Or booths outlet of a booth - risk assessment has been created assess spray... Painting may be used for touch up tX { S 9b2 '' 5 minutes after spraying with booth.! Of contamination ( for example dust or fumes generated by sanding and surface.! Application process > for mass produced items requiring a continuous painting application process the air chemical... Assignments like me, check out www.HelpWriting.net of contamination ( for example, in containers with lids to prevent forming. Be kept At a safe distance from spray painting and powder paints contain flammable substances '', ''! Noise from plant and injection injury to prevent flammable forming sand ( based on preliminary animal )!The following chemicals must not be used, handled or stored for spray painting: benzene (benzol), if the substance contains more than 1 per cent by volume, methanol (methyl alcohol), if the substance contains more than 1 per cent by volume, tetrachloromethane (carbon tetrachloride), and. By whitelisting SlideShare on your ad-blocker, you are supporting our community of content creators. What is required to manage risks associated with spray painting and powder coating?

performing work at height in a manner that allows workers to form a comfortable position, reducing the amount of force necessary to perform tasks, for example by using rigging. A tower to be used if high work required.

Respirators should closely fit the wearer to provide its designed protection, it is essential that an adequate face seal is achieved.

2. Electrical equipment should be kept at a safe distance from spray painting exclusion zones. !W,/0D, Audiometric testing must be provided to a worker who is frequently required to use personal protective equipment to protect the worker from the risk of hearing loss associated with noise that exceeds the exposure standard.

Spray painting including electrostatic spray painting, is a process by which liquid paint is applied under pressure to an object.

0000003456 00000 n Weve updated our privacy policy so that we are compliant with changing global privacy regulations and to provide you with insight into the limited ways in which we use your data. regular visual checks of equipment and plant including engineering controls and ventilation systems, regular monitoring and testing of ventilation flow rates, regular servicing of all equipment and plant, procedures for reporting and repairing faulty equipment, and, records of servicing, maintenance, repair and testing of plant and equipment should be kept, spraying equipment is regularly cleaned and maintained in accordance with the manufacturers instructions, spray booths are cleaned regularly.

the proper use, wearing, storage and maintenance of personal protective equipment (PPE), working in hazardous environments such as confined spaces, how to access SDSs for workers using, handling or storing hazardous chemicals, and.

endstream endobj 287 0 obj<>/OCGs[289 0 R]>>/PieceInfo<>>>/LastModified(D:20050420154544)/MarkInfo<>>> endobj 289 0 obj<>/PageElement<>>>>> endobj 290 0 obj<>/Font<>/XObject<>/ProcSet[/PDF/Text/ImageC]/ExtGState<>/Properties<>>>/StructParents 0>> endobj 291 0 obj<> endobj 292 0 obj<> endobj 293 0 obj<> endobj 294 0 obj<> endobj 295 0 obj<> endobj 296 0 obj[/ICCBased 321 0 R] endobj 297 0 obj<> endobj 298 0 obj<> endobj 299 0 obj<> endobj 300 0 obj<> endobj 301 0 obj<>stream

0000019829 00000 n

We've encountered a problem, please try again.