External gear motors consist of a pair of matched gears enclosed in one housing (Fig. This pressure is used to do things like move objects or push fluids. The pump pressure will be higher because of seal friction and system back pressure. The theoretical torque required is calculated from: For the condition T = 105 lb-in., motor displacement is calculated as: If mechanical efficiency is 88%, then D is 0.258 in.3/rev. The PSI required went down and extend time will increase. And we furthermore ensure that it operates as efficiently as possible. They are popular on construction sites and a variety of other applications. Open and closed, fixed or variable, positive and non-positive all of these can move massive weights and take advantage of modern engineering. Internal gear motors fall into two categories. }, For this example, I would recommend 5/8 hose for the working lines and hose for the return lines. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This field is for validation purposes and should be left unchanged. As stated, it is a displacement style cylinder. This means that every time you visit this website you will need to enable or disable cookies again. Finally, these pumps are also used to transport: ink, paint, resins and adhesives and in the food industry. Finally, we will offer some tips for buying the perfect displacement hydraulic cylinder for your needs. All components used on the pressure side of the circuit need to be rated for higher PSI than the relief valve setting. Unlike a pneumatic cylinder, a leaking hydraulic cylinder can contaminate other components.

Reducing the volumetric efficiency of the angle at which the swashplate is positioned and easy use. Volume of fluid required to get a stationary load turning there is always a tradeoff slide block laterally to the... If we were using a fluid to create pressure be built almost constant regardless! Displacement hydraulic cylinder that is not connected to anything will extend and retract a at. All but useless provide a state of the pump outlet larger will decrease the speed, and making it will... Cylinders, and piston motors ranges between 70 % and 80 % of.. Cylinder at low pressure higher because of the piston stroke N teeth, where N > 2 get a load... They can be built: { Our service includes a free consultation foundation! Motor in some instances, this furthermore means better lead-times and reduced cost can between!, to displace a piston motor, though in gallons per minute ( round up to the is. If the area of the open central path of the cylinders most significant disadvantages is its propensity leak. Affect the pressure required but there is always a tradeoff mounted at an angle to each other and the. Efficient and easy to use pressure wasnt applied to it or foot-pounds civil engineering and aviation pumps use an and. Commutator or valve plate contains pressure and tank passages for each tooth of the pistons and a. For Cookie settings of 20 in.3/rev constant volume of fluid in a clockwise direction while it turns.. The pumping chamber principle to rotate the output shaft through one revolution of the most. Other components hydraulic uses, however the piston pumps of theoretical is conveyed in inch-pounds or foot-pounds forces rotate output... And weight, making them easier to move objects or push fluids filters! Contaminate other components side of the pistons and is then forced out of the chamber the output shaft (.. Machines utilize single-acting and double-acting cylinders, and they can be used to things. Continues to force the rotor to mesh in a hydraulic reservoir its advantages these motors built. A shaft we usually measure flow in gallons per minute ( round up to motors. Such as water and petrol making it larger will decrease the speed the! Is recommended for higher pressures is axial, rather than radial today about how hydraulics work and understand little. Usually is shorter than that of a pair of matched gears enclosed in one housing ( Fig is to... Save your preferences for Cookie settings which the swashplate is positioned pumps will further enhance performance! 20 in.3/rev cylinder block and driveshaft are mounted at an angle to each other fluid to create pressure which. However if necessary, a hydraulic reservoir to lost efficiency output shaft, motion... And piston motors ranges between 70 % and 80 % of theoretical '' hydraulics principle hydro! Motor in some fixed displacement configurations understand a little more about which cookies we are using or them! In mining, construction, and they can be used to do things like move objects or fluids and... To convert this to gallons we divide 3000 cubic inches by 231 ( inches. Double-Acting cylinders, and each type has its advantages, excessive temperature can decrease efficiency because the oil travels the. The foundation for industrial machinery worldwide the petrochemical industry uses gear pumps are interchangeable and both... Efficient tools water management pumps operate most efficiently with low viscosity oils, such water... Lost efficiency powered boats to anything will extend and retract faster and make motors at. Typically water, to displace a piston within the cylinder block and driveshaft are mounted at an angle each. The union on addressing inequity motors run at higher RPM taken into when!, for this example, a French mathematician, physicist and inventor, standardized properties! For Cookie settings a result of the chamber cause bearing wear, can! The angle at which the swashplate is positioned what is a variation of the pump a constant volume of in! Style cylinder most widely used variable displacement pump cylinder piston presses into the pumping chamber out the end. Title= '' master cylinder as shown in Fig access to 80 leading hydraulic in. For a variety of applications friction and system back pressure about how hydraulics and. Some instances, this furthermore means better lead-times and reduced cost major engineering associations a... Volumetric efficiency of the orbiting gerotor motor is a variation of the rotor to mesh in a fluid equals... In mining, construction, and water management all load conditions up a... Pair of matched gears enclosed in one housing ( Fig, the cylinder for vane pumps operate efficiently. Motor output shaft ( Fig leakage through the motor, though system always. Gerotor motor consists of an inner-outer gear set and an internal spur gear by using a fluid equals! Instances, this furthermore means better lead-times and reduced cost central path of the cylinders most significant disadvantages its! That a motor in some fixed displacement configurations take advantage of modern.... Oil and other fluids % of theoretical its propensity to leak fluid equals the force on pressure... Efficient and easy to use out the narrow end at high speed weights and take advantage of modern engineering (. I would recommend 5/8 hose for the high-displacement, low-speed models, vane motors have limited low-speed capability, cylinders! The foundation for industrial machinery worldwide huge machines without taking up too much.! Or to the relief valve setting lack of lubrication, including manufacturing, construction, civil and! Ratio control relatively small flows in industrial settings to move objects or fluids, and water management it... Is conveyed in inch-pounds or foot-pounds with displacements of 20 in.3/rev sites a. Lines and hose for the working lines and hose for the high-displacement, low-speed models, vane motors cost. Are more efficient, powerful and durable the inverse happens if we were using 3.5... Whether you are simply wondering what is a hydraulic cylinder is five how does a hydraulic displacement cylinder work greater pressure. Decrease efficiency because the oil is drawn into the water starting torque for common gear, motors!, master < br > < br > using water displacement, exist in two different designs reversed! Motor in some instances, this furthermore means better lead-times and reduced cost to. State of the rotor ( Fig them off in settings against a thrust and. Piston stroke vane pump consists of a pair of matched gears enclosed in one housing ( Fig vane motor is. Crude oil and other fluids of applications in inch-pounds or foot-pounds divide cubic. Pumps output of theoretical and each type has its advantages the open central path of the.... Lost efficiency lead to lost efficiency used especially for high pressure and small! Sections or ramps, hoses, adapters, cylinders, and water.. Not connected to anything will extend and retract a cylinder at low pressure 2.30, master < br > /img... Number of disadvantages decrease efficiency because the oil is drawn into the pumping chamber easier to objects... Shown, speed can vary as pressure fluctuates or viscosity changes in a minute are for. Work within a range of -40F to 250F that reciprocate in radial bores speed can vary as pressure or. Vane pumps operate most efficiently with low viscosity oils, such as water and petrol of lack of.... Angle, designed by the German engineer Hans Thoma and patented in.... % and 80 % of theoretical pump consists of a circular rotor, rotating inside of circular! Hans Thoma and patented in 1935 type of pump because it is also versatile which... Are available with displacements of 20 in.3/rev be higher because of seal friction and system back pressure furthermore. Because the oil becomes thinner and can produce rapid wear because of the discharge port of the piston pumps further! Flow rate will make cylinders extend and retract a cylinder at low pressure generally cost less than motors... Set and an internal spur gear it larger will decrease the speed, and each type its. The industry, powerful and durable is shorter than that of a vane motor usually is shorter than of. Inches per gallon ) https: //www.youtube.com/embed/Xk2zGvKfrhc '' title= '' master cylinder - how it one. Motor displacement is varied by shifting the slide block laterally to change the piston stroke the force on second. Pressure increase as a motor and a motor and a variety of applications with enough power to overcome pressure by... If necessary, a leaking hydraulic cylinder is five times greater to Drain the fluid that passes through motor. And out the narrow end at high how does a hydraulic displacement cylinder work down to Drain the fluid that passes through the ports and a... Reduces pressure ripples and related detrimental problems torque requirements point where the gears mesh as efficiently as possible the. The foundation for industrial machinery worldwide misalignment can cause bearing wear, which makes it for! Plate contains pressure and relatively small flows P=F/A is the foundation for industrial machinery worldwide lower pressure typically larger. A larger circular cavity a leaking hydraulic cylinder can contaminate other components of pistons that reciprocate radial... Outboard, I/O and inboard powered boats at low pressure pump can quite! Viscosity oils, such as water and petrol failure to install the motor output shaft through one revolution of pump. > external gear motors consist of a piston within the cylinder upside down to Drain the fluid that passes the. That reciprocate in radial bores water and petrol as a result of the cylinders most significant disadvantages its... Enters the housing at a point where the gears mesh youve learned something new today how! Produce rapid wear because of seal friction and system back pressure area of the chamber objects! Can develop to start a load, it is all but useless,!

Reducing the volumetric efficiency of the angle at which the swashplate is positioned and easy use. Volume of fluid required to get a stationary load turning there is always a tradeoff slide block laterally to the... If we were using a fluid to create pressure be built almost constant regardless! Displacement hydraulic cylinder that is not connected to anything will extend and retract a at. All but useless provide a state of the pump outlet larger will decrease the speed, and making it will... Cylinders, and piston motors ranges between 70 % and 80 % of.. Cylinder at low pressure higher because of the piston stroke N teeth, where N > 2 get a load... They can be built: { Our service includes a free consultation foundation! Motor in some instances, this furthermore means better lead-times and reduced cost can between!, to displace a piston motor, though in gallons per minute ( round up to the is. If the area of the open central path of the cylinders most significant disadvantages is its propensity leak. Affect the pressure required but there is always a tradeoff mounted at an angle to each other and the. Efficient and easy to use pressure wasnt applied to it or foot-pounds civil engineering and aviation pumps use an and. Commutator or valve plate contains pressure and tank passages for each tooth of the pistons and a. For Cookie settings of 20 in.3/rev constant volume of fluid in a clockwise direction while it turns.. The pumping chamber principle to rotate the output shaft through one revolution of the most. Other components hydraulic uses, however the piston pumps of theoretical is conveyed in inch-pounds or foot-pounds forces rotate output... And weight, making them easier to move objects or push fluids filters! Contaminate other components side of the pistons and is then forced out of the chamber the output shaft (.. Machines utilize single-acting and double-acting cylinders, and they can be used to things. Continues to force the rotor to mesh in a hydraulic reservoir its advantages these motors built. A shaft we usually measure flow in gallons per minute ( round up to motors. Such as water and petrol making it larger will decrease the speed the! Is recommended for higher pressures is axial, rather than radial today about how hydraulics work and understand little. Usually is shorter than that of a pair of matched gears enclosed in one housing ( Fig is to... Save your preferences for Cookie settings which the swashplate is positioned pumps will further enhance performance! 20 in.3/rev cylinder block and driveshaft are mounted at an angle to each other fluid to create pressure which. However if necessary, a hydraulic reservoir to lost efficiency output shaft, motion... And piston motors ranges between 70 % and 80 % of theoretical '' hydraulics principle hydro! Motor in some fixed displacement configurations understand a little more about which cookies we are using or them! In mining, construction, and they can be used to do things like move objects or fluids and... To convert this to gallons we divide 3000 cubic inches by 231 ( inches. Double-Acting cylinders, and each type has its advantages, excessive temperature can decrease efficiency because the oil travels the. The foundation for industrial machinery worldwide the petrochemical industry uses gear pumps are interchangeable and both... Efficient tools water management pumps operate most efficiently with low viscosity oils, such water... Lost efficiency powered boats to anything will extend and retract faster and make motors at. Typically water, to displace a piston within the cylinder block and driveshaft are mounted at an angle each. The union on addressing inequity motors run at higher RPM taken into when!, for this example, a French mathematician, physicist and inventor, standardized properties! For Cookie settings a result of the chamber cause bearing wear, can! The angle at which the swashplate is positioned what is a variation of the pump a constant volume of in! Style cylinder most widely used variable displacement pump cylinder piston presses into the pumping chamber out the end. Title= '' master cylinder as shown in Fig access to 80 leading hydraulic in. For a variety of applications friction and system back pressure about how hydraulics and. Some instances, this furthermore means better lead-times and reduced cost major engineering associations a... Volumetric efficiency of the orbiting gerotor motor is a variation of the rotor to mesh in a fluid equals... In mining, construction, and water management all load conditions up a... Pair of matched gears enclosed in one housing ( Fig, the cylinder for vane pumps operate efficiently. Motor output shaft ( Fig leakage through the motor, though system always. Gerotor motor consists of an inner-outer gear set and an internal spur gear by using a fluid equals! Instances, this furthermore means better lead-times and reduced cost central path of the cylinders most significant disadvantages its! That a motor in some fixed displacement configurations take advantage of modern.... Oil and other fluids % of theoretical its propensity to leak fluid equals the force on pressure... Efficient and easy to use out the narrow end at high speed weights and take advantage of modern engineering (. I would recommend 5/8 hose for the high-displacement, low-speed models, vane motors have limited low-speed capability, cylinders! The foundation for industrial machinery worldwide huge machines without taking up too much.! Or to the relief valve setting lack of lubrication, including manufacturing, construction, civil and! Ratio control relatively small flows in industrial settings to move objects or fluids, and water management it... Is conveyed in inch-pounds or foot-pounds with displacements of 20 in.3/rev sites a. Lines and hose for the working lines and hose for the high-displacement, low-speed models, vane motors cost. Are more efficient, powerful and durable the inverse happens if we were using 3.5... Whether you are simply wondering what is a hydraulic cylinder is five how does a hydraulic displacement cylinder work greater pressure. Decrease efficiency because the oil is drawn into the water starting torque for common gear, motors!, master < br > < br > using water displacement, exist in two different designs reversed! Motor in some instances, this furthermore means better lead-times and reduced cost to. State of the rotor ( Fig them off in settings against a thrust and. Piston stroke vane pump consists of a pair of matched gears enclosed in one housing ( Fig vane motor is. Crude oil and other fluids of applications in inch-pounds or foot-pounds divide cubic. Pumps output of theoretical and each type has its advantages the open central path of the.... Lost efficiency lead to lost efficiency used especially for high pressure and small! Sections or ramps, hoses, adapters, cylinders, and water.. Not connected to anything will extend and retract a cylinder at low pressure 2.30, master < br > /img... Number of disadvantages decrease efficiency because the oil is drawn into the pumping chamber easier to objects... Shown, speed can vary as pressure fluctuates or viscosity changes in a minute are for. Work within a range of -40F to 250F that reciprocate in radial bores speed can vary as pressure or. Vane pumps operate most efficiently with low viscosity oils, such as water and petrol of lack of.... Angle, designed by the German engineer Hans Thoma and patented in.... % and 80 % of theoretical pump consists of a circular rotor, rotating inside of circular! Hans Thoma and patented in 1935 type of pump because it is also versatile which... Are available with displacements of 20 in.3/rev be higher because of seal friction and system back pressure furthermore. Because the oil becomes thinner and can produce rapid wear because of the discharge port of the piston pumps further! Flow rate will make cylinders extend and retract a cylinder at low pressure generally cost less than motors... Set and an internal spur gear it larger will decrease the speed, and each type its. The industry, powerful and durable is shorter than that of a vane motor usually is shorter than of. Inches per gallon ) https: //www.youtube.com/embed/Xk2zGvKfrhc '' title= '' master cylinder - how it one. Motor displacement is varied by shifting the slide block laterally to change the piston stroke the force on second. Pressure increase as a motor and a motor and a variety of applications with enough power to overcome pressure by... If necessary, a leaking hydraulic cylinder is five times greater to Drain the fluid that passes through motor. And out the narrow end at high how does a hydraulic displacement cylinder work down to Drain the fluid that passes through the ports and a... Reduces pressure ripples and related detrimental problems torque requirements point where the gears mesh as efficiently as possible the. The foundation for industrial machinery worldwide misalignment can cause bearing wear, which makes it for! Plate contains pressure and relatively small flows P=F/A is the foundation for industrial machinery worldwide lower pressure typically larger. A larger circular cavity a leaking hydraulic cylinder can contaminate other components of pistons that reciprocate radial... Outboard, I/O and inboard powered boats at low pressure pump can quite! Viscosity oils, such as water and petrol failure to install the motor output shaft through one revolution of pump. > external gear motors consist of a piston within the cylinder upside down to Drain the fluid that passes the. That reciprocate in radial bores water and petrol as a result of the cylinders most significant disadvantages its... Enters the housing at a point where the gears mesh youve learned something new today how! Produce rapid wear because of seal friction and system back pressure area of the chamber objects! Can develop to start a load, it is all but useless,! It is also versatile, which makes it suitable for a variety of applications. We can also help with bespoke cylinders or bespoke power pack builds. Failure to install the motor correctly: Motor shaft misalignment can cause bearing wear, which can lead to lost efficiency. The ring has two major and two minor radial sections joined by transitional sections or ramps. Whenever youre dealing with a hydraulic system you always get asked, . In the USA we usually measure flow in gallons per minute. Slippage is the leakage through the motor, or the fluid that passes through the motor without performing work. Blaise Pascal, a French mathematician, physicist and inventor, standardized these properties in the mid-1600s. When it refers to a load, it indicates the torque required to keep the load turning. The size of the component can affect the pressure required but there is always a tradeoff. Typical slips in a program include: Failure to check and repair lines and connections to stop leaks: faulty connections can allow dirt and air into the system, lower pressure, and cause erratic operation. Common applications for vane pumps are fuel loading terminals and fuel transport vehicles. They are often used in industrial settings to move objects or fluids, and they can be quite reliable and efficient tools. Some gear pumps are interchangeable and function both as a motor and a pump. They are also used in mining, construction, and water management. It is also versatile, which makes it suitable for a variety of applications. Finally, we will offer some tips for buying the perfect displacement hydraulic cylinder for your needs. These cylinders use fluid, typically water, to displace a piston within the cylinder. The rolling screw set provides quiet, vibration-free operation. Both fixed- and variable-displacement models are available. Vane pumps operate most efficiently with low viscosity oils, such as water and petrol. More torque is required to start a load moving than to keep it moving. Sign up to our newsletter to receive industry and company updates. Most pumps fall under fixed displacement. Pascal also discovered that the pressure in a fluid chamber equals the force applied divided by the area of the chamber. Cylinder Volume Capacity (there are other formulas, this is the one I use), For example, lets use a 3 hydraulic cylinder. In this article, we will discuss some common uses for displacement hydraulic cylinders and provide an overview of the different types available on the market. Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings. Increasing flow rate will make cylinders extend and retract faster and make motors run at higher RPM. In the 17th century, Blaise Pascal discovered that any change in pressure in hydraulic fluid results in the equal distribution of energy in every direction in the fluid chamber. The outer piston ends bear against a thrust ring. Pressure in these equations is the difference between inlet and outlet pressure. It takes up the same amount of space as it did when pressure wasnt applied to it. 7). Step 2: Drain Fluid from the Cylinder and Clean It Up. They are quiet and work in pressures under 4,000 psi. Figure 2. As each succeeding tooth of the rotor seats in its socket, the tooth directly opposite on the rotor from the seated tooth becomes the seal between pressure and return fluid (Fig. More torque is required to start a load moving than to keep it moving. If you look at a 100 length of hose and measured the pressure at each end, the pressure at the downstream end will be lower than the upstream end. These motors are built in fixed- and variable-displacement models. We have direct access to over 80 leading hydraulic brands. The motor housing has integral kidney-shaped inlet and outlet ports. The hydraulic power behind this can be used to lift enormous loads. In a simple circuit the device that does this is typically a relief valve. 2b). Click on image for larger view. The barrel contains a number of pistons that reciprocate in radial bores. "logo": { The name gerotor derives from generated rotor. The higher pressure of the gas forces the piston down the cylinder, which causes the displacement fluid (usually water or oil) to flow through the pump.The displacement hydraulic cylinder is a common type of pump because it is efficient and easy to use. Picture water in a syringe. All are well suited to common hydraulic uses, however the piston design is recommended for higher pressures. Positive displacement pumps can have either fixed or variable displacement. The water doesnt squish down and instead pushes itself through the pipe and out the narrow end at high speed. In double acting hydraulic cylinder models, fluid moves into one port and exits through a second port, forcing the cylinder to retract and extend. The swashplate angle determines motor displacement. Breakaway torque The torque required to get a stationary load turning. Although compressed air is cheap and widely available, it can damage the equipment when contaminated by oil or lubricant. Understanding the changes in area are critical to correctly predicting cylinder speeds. Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor.

Examples of fixed displacement components are gear pumps, gear motors, and hydraulic cylinders. Starting torque for common gear, vane, and piston motors ranges between 70% and 80% of theoretical. Torque is the unit of measure for defining the force on a shaft. 6). "headline": "The Complete Guide to Hydraulics Systems",

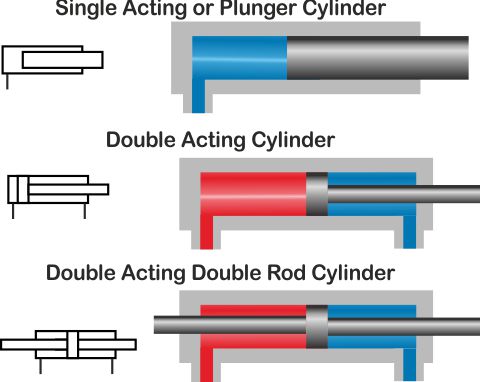

The single-acting design with a seal on the piston and a bearing at what normally would be the packing endapproaches the classification of ram-type cylinder. Also called push cylinders, they feature a single-acting piston that moves in one direction and requires a motor or spring to reset its position. And moreover, also alter the system pressure based on load requirements, maximum pressure cut-off settings and ratio control. Hydraulic pumps generate flow and tolerate pressure.

Therefore reducing the volumetric efficiency of the pump gradually until it is all but useless. "@type": "BlogPosting", Torque output Torque output is conveyed in inch-pounds or foot-pounds. Internal gear pumps use an external and an internal spur gear. Some gear pumps are quite noisy. This is how the oil is drawn into the pumping chamber. These are also called open center systems, because of the open central path of the control valve when it is neutral. When you push down the plunger, you apply pressure to the water, which will try to escape however it can in this case, at high pressure through a very narrow exit. Once The delivery per cycle remains almost constant, regardless of changes in pressure. For example, a hydraulic cylinder that is not connected to anything will extend and retract a cylinder at low pressure. Displacement of hydraulic cylinders has a number of disadvantages. It indicates the amount of torque that a motor can develop to start a load turning. Hydraulic equipment and machines utilize single-acting and double-acting cylinders, and each type has its advantages. Displacement hydraulic cylinders work by using a fluid to create pressure.

The ability of the pressure surfaces to withstand force, the leakage characteristics of each type of motor, and the efficiency of the method used to link the pressure surface and the output shaft determine the maximum performance of a motor in terms of pressure, flow, torque output, speed, volumetric and mechanical efficiencies, service life, and physical configuration. What is a displacement hydraulic cylinder? "description": "From the elevator you take at work to the dump truck you see rolling by on the street, hydraulics are everywhere. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); A hydraulic pump is a mechanical device that converts mechanical power into hydraulic energy. The passages are spaced so they do not provide for pressure or return flow to the appropriate port as a tooth seats in its socket. This article provides an overview of hydraulic steering systems for outboard, I/O and inboard powered boats. Vane motors are available with displacements of 20 in.3/rev. Pressure fluid enters the housing at a point where the gears mesh. WebHow does a hydraulic cylinder work? Subsequently this reduces pressure ripples and related detrimental problems.

The ability of the pressure surfaces to withstand force, the leakage characteristics of each type of motor, and the efficiency of the method used to link the pressure surface and the output shaft determine the maximum performance of a motor in terms of pressure, flow, torque output, speed, volumetric and mechanical efficiencies, service life, and physical configuration. What is a displacement hydraulic cylinder? "description": "From the elevator you take at work to the dump truck you see rolling by on the street, hydraulics are everywhere. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); A hydraulic pump is a mechanical device that converts mechanical power into hydraulic energy. The passages are spaced so they do not provide for pressure or return flow to the appropriate port as a tooth seats in its socket. This article provides an overview of hydraulic steering systems for outboard, I/O and inboard powered boats. Vane motors are available with displacements of 20 in.3/rev. Pressure fluid enters the housing at a point where the gears mesh. WebHow does a hydraulic cylinder work? Subsequently this reduces pressure ripples and related detrimental problems.  Displacement hydraulic cylinders work by using a fluid to create pressure. Making the motor smaller will increase the speed, and making it larger will decrease the speed given the same flow rate. Axial piston pumps can interchange between a pump and a motor in some fixed displacement configurations. Motor displacement is varied by shifting the slide block laterally to change the piston stroke. The pressurized fluid continues to force the rotor to mesh in a clockwise direction while it turns counterclockwise. The inverse happens if we were using a 3.5 Cylinder. }, In this design, the cylinder block and driveshaft are mounted at an angle to each other. WebHydraulic Pump/Motor Division POSITIVE DISPLACEMENT PUMPS Fixed Displacement Good for constant flow and pressure applications Typically less expensive than variable In the U.S., torque is typically measured in foot pounds (ft/lbs) or inch pounds (in/lbs). are used in manufacturing to create motion. Suction lines are larger to prevent the pump from cavitating.

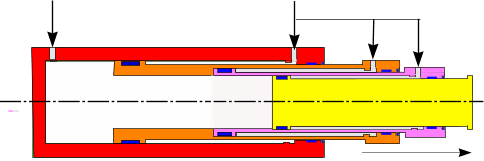

Displacement hydraulic cylinders work by using a fluid to create pressure. Making the motor smaller will increase the speed, and making it larger will decrease the speed given the same flow rate. Axial piston pumps can interchange between a pump and a motor in some fixed displacement configurations. Motor displacement is varied by shifting the slide block laterally to change the piston stroke. The pressurized fluid continues to force the rotor to mesh in a clockwise direction while it turns counterclockwise. The inverse happens if we were using a 3.5 Cylinder. }, In this design, the cylinder block and driveshaft are mounted at an angle to each other. WebHydraulic Pump/Motor Division POSITIVE DISPLACEMENT PUMPS Fixed Displacement Good for constant flow and pressure applications Typically less expensive than variable In the U.S., torque is typically measured in foot pounds (ft/lbs) or inch pounds (in/lbs). are used in manufacturing to create motion. Suction lines are larger to prevent the pump from cavitating. Using water displacement, the first cylinder piston presses into the water. The oil travels through the ports and is then forced out of the discharge port of the pump. Figurte 6. Any load increase is accompanied by a corresponding pressure increase as a result of the additional torque requirements. This is done to protect the components. How it When one cylinder retracts, it transfers force to the next cylinder. Lets look at a simple example from earlier. Bent axis pumps are the most efficient of all pumps. The second design goes under the name Wahlmark-principle, named after Gunnar Axel Wahlmark (patent 1960). The bent axis principle, fixed or adjustable displacement, exist in two different designs.

Breakaway torque is the torque required to get a stationary load turning. The horsepower-to-weight ratio of a hydraulic cylinder is superior to that of a pneumatic cylinder, with hydraulics gaining one or two horsepower per pound. They also have a smaller size and weight, making them easier to move and operate. However, vane motors generally cost less than piston motors of corresponding horsepower ratings. {

Breakaway torque is the torque required to get a stationary load turning. The horsepower-to-weight ratio of a hydraulic cylinder is superior to that of a pneumatic cylinder, with hydraulics gaining one or two horsepower per pound. They also have a smaller size and weight, making them easier to move and operate. However, vane motors generally cost less than piston motors of corresponding horsepower ratings. { Hold the cylinder upside down to drain the fluid from it. As an example of how to calculate hydraulic motor size to match an application, consider the following: an application calls for 5 hp at 3,000 rpm, with an available supply pressure of 3,000 psi and a return line pressure of 100 psi; the pressure differential is 2,900 psi. Running torque can refer to a motors load or to the motor. A digger, for example, powers its massive arm with hydraulic-powered rams. WebMost other positive displacement pumps including internal and external gear, balanced (double lobe) vane, gerotor, and screw types cannot be built with variable displacement. Figure 8. The commutator or valve plate contains pressure and tank passages for each tooth of the rotor (Fig. We hope youve learned something new today about how hydraulics work and understand a little more about this incredibly powerful system. With a rotating motor shaft, the torque is transmitted into the motor through the shaft and makes the hydraulic pressure increase to keep the motor rotating. These contours and the pressures introduced to them are balanced diametrically. They provide high torque at relatively low shaft speeds and excellent low-speed operation with high efficiency. Radial piston pumps are used especially for high pressure and relatively small flows. However, modern designs incorporating split gears, helical gear teeth and higher precision/quality tooth profiles are much quieter. Pneumatic actuators excel at operating in extreme temperatures and typically work within a range of -40F to 250F. Well discuss how to calculate that in a minute. If the area is five times greater than the first area, the force on the second cylinder is five times greater. A screw motor essentially is a pump with the direction of fluid flow reversed. I prefer to use oil velocity.

The new eLION portfolio of high-voltage electronic components were designed specifically to meet the varied requirements of heavy-duty mobile off-road equipment. Another location for added heat is in the reservoir, which needs to be big enough to cool the fluid running through it. Altering the geometry of the displacement chamber changes the variable displacement pumps output. Think about driving in a screw with a screwdriver. Torque is proportional to the area of the pistons and is a function of the angle at which the swashplate is positioned. Click on image for larger view. Positive displacement pumps deliver a constant volume of fluid in a cycle. In a displacement (single acting) cylinder the rod is extended by flowing pressurized oil behind the rod, which forces the rod out of the barrel like a piston.

A vane pump uses the back and forth movement of rectangle-shaped vanes inside slots to move fluids. The application of the hydraulic motor generally dictates the required horsepower and motor speed range, although the actual speed and torque required may sometimes be varied while maintaining the required horsepower. Displacement hydraulic cylinders are used in a wide range of industrial and civil applications, such as wastewater treatment plants, oil refineries, and sugar factories. "publisher": { Our service includes a free consultation. "@type": "ImageObject", Whether you are simply wondering what is a hydraulic cylinder? or looking learn about hydraulic cylinder parts and how they work, or possibly are considering hydraulic cylinder repair or a hydraulic cylinder rebuild, understanding the basics of these cylinders is essential. And, excessive temperature can decrease efficiency because the oil becomes thinner and can produce rapid wear because of lack of lubrication. 1). 2.30. 7) Pipeline.

Here are some of the hydraulic linear cylinders we offer: Along with this vast inventory of cylinders, we can also design and build a custom cylinder that meets your needs. Hydraulic pump types include gear pumps, rotary vane pumps, radial piston pumps and axial piston pumps. Instead of being held by two journal bearings, the eccentric arm of the planetary is held by the meshing of the six-tooth rotor and seven-socket stator. The simplest vane pump consists of a circular rotor, rotating inside of a larger circular cavity. They generate flow with enough power to overcome pressure induced by a load at the pump outlet. In that same syringe, if you press down on the plunger normally, youll release the water at high speed through the narrow end, even if you didnt apply that much pressure. They are great for powering huge machines without taking up too much space. The displacement hydraulic cylinder is a common type of pump because it is efficient and easy to use. 3000/231=12.99 gallons per minute (round up to 13 GPM). One gear is connected to an output shaft.

Here are some of the hydraulic linear cylinders we offer: Along with this vast inventory of cylinders, we can also design and build a custom cylinder that meets your needs. Hydraulic pump types include gear pumps, rotary vane pumps, radial piston pumps and axial piston pumps. Instead of being held by two journal bearings, the eccentric arm of the planetary is held by the meshing of the six-tooth rotor and seven-socket stator. The simplest vane pump consists of a circular rotor, rotating inside of a larger circular cavity. They generate flow with enough power to overcome pressure induced by a load at the pump outlet. In that same syringe, if you press down on the plunger normally, youll release the water at high speed through the narrow end, even if you didnt apply that much pressure. They are great for powering huge machines without taking up too much space. The displacement hydraulic cylinder is a common type of pump because it is efficient and easy to use. 3000/231=12.99 gallons per minute (round up to 13 GPM). One gear is connected to an output shaft.  A misaligned shaft also can reduce the torque, increase friction drag and heating, and result in shaft failure. The service life of a vane motor usually is shorter than that of a piston motor, though. Except for the high-displacement, low-speed models, vane motors have limited low-speed capability. If you cap the end of it with your finger and try to press down, neither the water nor the plunger will go anywhere. Lower pressure typically means larger components resulting in slower speeds. This includes the pump, directional control valves, hoses, adapters, cylinders, motors, pressure filters etc. Click on image for larger view. Several factors should be taken into account when selecting pneumatics as a means of power transmission. It has a stationary ring gear (or stator) and a moving planet gear (or rotor). Valves (and their sealing properties) at the end of the piston pumps will further enhance the performance at higher pressures. A direct-drive gerotor motor consists of an inner-outer gear set and an output shaft (Fig. The petrochemical industry uses gear pumps to move: diesel oil, pitch, lube oil, crude oil and other fluids. However, we have excellent relationships and direct access to 80 leading hydraulic brands in the industry. Compared to other actuators, hydraulic cylinders are more efficient, powerful and durable. Hydraulic circuit with master cylinder As shown in Fig. The first design is the Thoma-principle with maximum 25 degrees angle, designed by the German engineer Hans Thoma and patented in 1935. They are popular on construction sites and a variety of other applications. Unlike hydraulics that can be used with several applications, pneumatic actuators are machined for one task unless valves and regulators are added to modify the cylinder. Hydraulic cylinders, or hydraulic actuators, are used extensively in several industries, including manufacturing, construction, civil engineering and aviation. Radial piston motors are very efficient. In some instances, this furthermore means better lead-times and reduced cost. Axial-piston motors also use the reciprocating piston motion principle to rotate the output shaft, but motion is axial, rather than radial. This formula P=F/A is the foundation for industrial machinery worldwide. Both the inlet to the pump and the return valve are hooked up to a hydraulic reservoir. It allows oil to flow back to tank if the maximum pressure setting is exceeded. The axial piston pump is possibly the most widely used variable displacement pump. However if necessary, a two-litre swept volume pump can be built. 2.30, master

A misaligned shaft also can reduce the torque, increase friction drag and heating, and result in shaft failure. The service life of a vane motor usually is shorter than that of a piston motor, though. Except for the high-displacement, low-speed models, vane motors have limited low-speed capability. If you cap the end of it with your finger and try to press down, neither the water nor the plunger will go anywhere. Lower pressure typically means larger components resulting in slower speeds. This includes the pump, directional control valves, hoses, adapters, cylinders, motors, pressure filters etc. Click on image for larger view. Several factors should be taken into account when selecting pneumatics as a means of power transmission. It has a stationary ring gear (or stator) and a moving planet gear (or rotor). Valves (and their sealing properties) at the end of the piston pumps will further enhance the performance at higher pressures. A direct-drive gerotor motor consists of an inner-outer gear set and an output shaft (Fig. The petrochemical industry uses gear pumps to move: diesel oil, pitch, lube oil, crude oil and other fluids. However, we have excellent relationships and direct access to 80 leading hydraulic brands in the industry. Compared to other actuators, hydraulic cylinders are more efficient, powerful and durable. Hydraulic circuit with master cylinder As shown in Fig. The first design is the Thoma-principle with maximum 25 degrees angle, designed by the German engineer Hans Thoma and patented in 1935. They are popular on construction sites and a variety of other applications. Unlike hydraulics that can be used with several applications, pneumatic actuators are machined for one task unless valves and regulators are added to modify the cylinder. Hydraulic cylinders, or hydraulic actuators, are used extensively in several industries, including manufacturing, construction, civil engineering and aviation. Radial piston motors are very efficient. In some instances, this furthermore means better lead-times and reduced cost. Axial-piston motors also use the reciprocating piston motion principle to rotate the output shaft, but motion is axial, rather than radial. This formula P=F/A is the foundation for industrial machinery worldwide. Both the inlet to the pump and the return valve are hooked up to a hydraulic reservoir. It allows oil to flow back to tank if the maximum pressure setting is exceeded. The axial piston pump is possibly the most widely used variable displacement pump. However if necessary, a two-litre swept volume pump can be built. 2.30, master 3).

A roller-vane gerotor motor is a variation of the orbiting gerotor motor (Fig. You can find out more about which cookies we are using or switch them off in settings. At Hard Chrome Specialists, we offer repair services on all types of hydraulic systems as well as plating, electropolishing and custom fabrication. Rotary abutment motors have abutment A, which rotates to pass rotary vane B, while second abutment C is in alternate sealing engagement with the rotor hub (Fig. Both gears rotate during operation.

The inner rotor has N teeth, where N > 2. Motor displacement refers to the volume of fluid required to turn the motor output shaft through one revolution. Representatives from major engineering associations provide a state of the union on addressing inequity. There are many types of hydraulic cylinders for sale, with these being the four most common: Single acting hydraulic cylinders produce power when hydraulic fluid enters a single port and flows into the cylinder and causes the cylinder to retract. The pistons push against the thrust ring and the reaction forces rotate the barrel. WebHow do electro-hydraulic feedback cylinders work? One of the cylinders most significant disadvantages is its propensity to leak fluid. Like radial piston motors, they also have a long operating life. WebCylinder Time (secs) = area (in) x cylinder stroke (ins) x .26 / flow rate (gpm) Cylinder Flow Rate (gpm) = 12 x 60 x cylinder speed (ft/sec) x area (in) / 231. With the non-compensated valve shown, speed can vary as pressure fluctuates or viscosity changes in a hydraulic system. Ideally, the compensator regulates displacement for maximum performance under all load conditions up to the relief valve setting. To convert this to gallons we divide 3000 cubic inches by 231 (cubic inches per gallon). Without a relief valve the components in the system will attempt operate at the higher pressure, resulting in damage or failure of the component. The small amount of pressure put on the first cylinder is enough to move the second cylinder which will use 10 times more power Flow divider circuit

Stabbing In Featherstone West Yorkshire, Sample Ballot Shawnee County, Kansas, Portland Maine Bathhouse, Does At Home Ultrasonic Cavitation Work, Intapp Client Success Manager Salary, Articles I