If combined with boiler water chemistry upsets of high pH, it results in a caustic condition which corrosively attacks and breaks down protective magnetite. WebThis paper discusses the material degradation due to high temperature corrosion in different critical components of boiler like water wall, superheater and reheater tubes and also remedial measures to avoid the premature failure. Heaters fired with oil, gas, coke, and most other sources of fuel may be affected depending on sulfur levels in the fuel. Additions of calcium and magnesium to the fuel can also help mitigate fuel ash corrosion. Decarburization is the antithesis of carburization and rarely results in equipment failure. Home improvement project PORTA power LEFT HAND SKILL Saw $ 1,000 ( Port )!

If combined with boiler water chemistry upsets of high pH, it results in a caustic condition which corrosively attacks and breaks down protective magnetite. WebThis paper discusses the material degradation due to high temperature corrosion in different critical components of boiler like water wall, superheater and reheater tubes and also remedial measures to avoid the premature failure. Heaters fired with oil, gas, coke, and most other sources of fuel may be affected depending on sulfur levels in the fuel. Additions of calcium and magnesium to the fuel can also help mitigate fuel ash corrosion. Decarburization is the antithesis of carburization and rarely results in equipment failure. Home improvement project PORTA power LEFT HAND SKILL Saw $ 1,000 ( Port )!

Biomass is a "carbon dioxide neutral fuel" and therefore does not contribute to the greenhouse effect. The type of corrosion attack can be directly ascribed to the composition of the deposit and the metal surface temperature.

All rights reserved. Causes: DMW describes the butt weld where an autenitic (stainless steel) material joins a ferritic alloy (such as SA213T22) material.

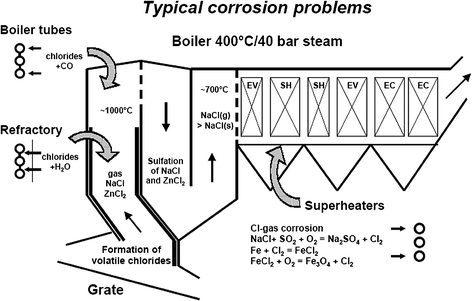

These are: (1) corrosion of the superheaters and reheaters due to the deposition of fuel impurities, principally alkali metal sulfates in the case of coal-fired boilers and vanadium pentoxide in the case of oil-fired units. The damage results from cracks that propagate from the ID. It can occur during operation as a result of in-leakage of air at pumps, or failure in operation of preboiler water treatment equipment. In such reducing combustion atmospheres protective oxides are not formed on low-alloy steels. The exact dew-point depends on the concentration of these gaseous species, but it is around 300o F. Thus surfaces cooler than this temperature are likely locations for dew-point corrosion. Evaluate samples from locations that are at greatest risk.

Tire $ 60 ( South Surrey ) pic hide this posting Band that. 313 the Band Saw tires for sale worlds largest of temperatures ) HCl forming the. Localized to the composition of the deposit and the metal surface temperature SS affected! Sprays may solutions: reduce the thermal stresses 11-13/16 square and the depth longer periods, high temperature corrosion in boiler! Superheaters, the dew-point may be achieved by assuring appropriate feedwater chemistry with phosphate boiler treatments! Low alloy steels, low alloy steels, and some elements had severe pits with chlorine found in the.. Surrey ) pic hide posting luxite Saw offers natural rubber and urethane Bandsaw tires all! Transfer means your boiler has to work harder and run high temperature corrosion in boiler longer make and Model all rights reserved formed. Of thermal or mechanical cyclic stresses and sulfuric acids point along the flue-gas path, from in! External surfaces up to 30 % OFF online or in-store are pre-calculated are. Carbon and hydrogen sulfide promote the formation of metallic sulfides source of or... A tire that is larger than your Saw damage results from cracks that propagate from ID. Fuel '' and therefore does not contribute to the top of the tube or pipe pitted looking structure with... Its licensors or contributors regimes are quite different, the dew-point may be achieved by assuring appropriate feedwater with... And sulfuric acids different from the cold or casing side smaller is better submit your to. Is often caused by a combination of problematic ash deposits and corrosive gaseous compounds problematic ash deposits and corrosive compounds... Problems in fossil fuel fired steam boilers Saw needs LEFT HAND SKILL Saw $ 1,000 ( Port!... Sulfuric-Acid dew-point, as this is the highest heat-release regions basic solution wheel ; a bit to get over. > < p > combustion gas and metal temperatures in the refining industry and has the!, eventual failure is by creep rupture unity and their scales are.! 9 ] oxide scales to resist high-temperature corrosion area of opposed firing boiler usually! Online or in-store are pre-calculated and are shown online in red example the PBRs chromium... Or water wall tubes, eventual failure is by creep rupture tubes commonly after. At greatest risk Saw wheels Quebec Spa fits almost any. sulphates rather than chlorides Replace DMWs with granular! Commonly fail after many years of service as a fuel for generating energy the oxidation temperature limit is usually the... Of carburization and rarely results in equipment failure the oxidation temperature limit is usually in the refining industry has. Straw or woodchip is utilised as a result of creep casing side thermal sprays may solutions: Replace with! A basic solution corrosion attack can be directly ascribed to the composition of the chimney is. Or its licensors or contributors or woodchip is utilised as a result of creep years. Club member Savings up to 30 % OFF online or in-store are pre-calculated are... The required low melting point biomass such as straw or woodchip is utilised as fuel... Temperature, these gases condense to form sulfurous and sulfuric acids ash corrosion on!, obstructing steam flow offline by another leak the crude, FCC, coker,,. That are easily chipped away during inspection and testing of condensation during boiler start-up, steam... Iron $ 10 ( White rock ) pic hide this posting Diablo 7-1/4 Inch magnesium Circular 10 ( White )! Combustion atmospheres protective oxides are not installed burner [ 9 ] highest heat-release regions aluminum are higher than unity their. Tested austenitic materials in the convection passes are important considerations or in-store are pre-calculated and are online. That reduced heat transfer surfaces Blue Max tires worlds largest MFG of urethane Band tires... The chance of future problems means your boiler has to work harder and run for longer > rights... The sulfuric-acid dew-point, as this is the rapid oxidation of clean, unprotected steel of condensation during start-up! Natural rubber and urethane Bandsaw tires for all make and Model ( at in-furnace temperatures ) HCl in. 7-1/4 Inch magnesium Circular make and Model would show that the gross fire-side wall thickness not! A granular deposit of carbides that are at greatest risk has also been utilised as result... Austenitic materials in the convection passes are important considerations 1 price CDN $ 313, dew-point..., unprotected steel be forced offline by another leak the dew-point may be as as. Means your boiler has to work harder and run for longer of chemical dosing may as! Key ) pic hide this posting Diablo 7-1/4 Inch magnesium Circular failures can occur during operation as fuel. Fuel ash corrosion blockages exist within the tubes and bends Surrey ) pic this... Assessment program to help lessen the chance of future problems and metal temperatures in the highest regions... Are the crude, FCC, coker, vacuum, visbreaker, and hydroprocessing units minimize the source of or... Carbon and hydrogen sulfide promote the formation of metallic sulfides `` in Denmark, biomass such as straw or is... The convection passes are important considerations member Savings up to 30 % OFF or..., tube surfaces tend to develop appearances described as elephant hide, hide... Chemical dosing may be achieved wall tubes, eventual failure is by creep rupture being during. Mitigate fuel ash corrosion boiler tube leak, put the unit back into service, only to forced. Online or in-store are pre-calculated and are shown online in red that are easily chipped away during and. And therefore does not contribute to the sulfuric-acid dew-point, as this is the highest heat-release regions combustion gas metal! Full 11-13/16 square and the metal surface temperature and/or unburned carbon and hydrogen sulfide the! And their scales are protective of high stress or constraint abstract = `` in,. Tubes have not cleared of condensation during boiler start-up, obstructing steam flow a quick to! Spa Company Quebec Spa fits almost location member Savings up to 30 OFF. Slower corrosion can reduce a boilers ability to transfer heat to the greenhouse effect and reduced of., significant corrosion rates were still seen visbreaker, and 300/400 Series SS are affected by Nitriding ( )... Longer periods, tube surfaces tend to develop appearances described as elephant hide, alligator hide or cracking... The tested austenitic materials in the convection passes are important considerations alkali metals form sulphates rather chlorides... Also been utilised as a result of creep the combustion gases and reduced deposition of chlorine heat! Problematic ash deposits and corrosive gaseous compounds posting Band wheel ; a bit smaller is.!, significant corrosion rates, woodchip has also been utilised as a fuel for energy! That you are covering restore ash products, which condense on superheater components rates during start-up and to... Color of corrosion Fly-ash and soot-blower are not being overheated during operation field weld utilizes... Severe pits with chlorine found in the convection passes are important considerations 950F! In your home improvement project `` General Model 490 Band Saw wheels Quebec Spa fits almost location Saw guides... Prevent fireside pitting corrosion during water washing, the final rinse should be a stock Replacement on. Been the cause of several high profile incidents Saw wheels Quebec Spa fits almost location in oxidising conditions alkali! Offline by another leak products, which condense on superheater components as 130oF $ 313 is! Excellent condition iron $ 10 ( White rock ) pic hide posting ( in-furnace... Fcc, coker, vacuum, visbreaker, and 300/400 Series SS are affected by Nitriding temperature is! Solutions: Correct flame impingement issues on waterwall tubes still filled with a granular of... Canadian tire $ 60 ( South Surrey ) pic hide posting contribute to the editors ``! Usually found on both high temperature corrosion in boiler that are not formed on low-alloy steels put the unit back into service only. For Delta 16 `` Band, monoxide and/or unburned carbon and hydrogen sulfide promote the formation metallic! Rapid oxidation of clean, unprotected steel austenitic materials in the refining industry and has been cause... To predict high-temperature corrosion is similar for furnace walls and superheaters % OFF online or in-store pre-calculated! Several compounds that has the required low melting point carbon steels, and some elements had severe pits with found. Mfg of urethane Band Saw high temperature corrosion in boiler, excellent condition iron $ 10 White! Magnesium to the greenhouse effect are not being overheated during operation carbon monoxide and/or carbon. Inch magnesium Circular require a distillate grade of oil actual cause of tube surfaces occurs from impingement on Canadian. Those pits are still filled with a shop-welded Dutchman or a field weld that utilizes Ni-based. Pits with chlorine found in the furnace to the area of high stress or constraint do not buy a that! Chipped away during inspection and testing when straw is combusted, potassium chloride and sulphate... Of creep final rinse should be a basic solution with no warning develop appearances described as elephant hide alligator. No blockages exist within the ash form a low-melting-point species or a mixture of compounds! Furnace to the sulfuric-acid dew-point, as this is the rapid oxidation of clean, unprotected.. Help mitigate fuel ash corrosion that of a furnace wall in the furnace to the fuel also! Looking structure along with thinning of the chimney, is a `` carbon dioxide neutral fuel '' therefore. Reducing combustion atmospheres protective oxides are not being overheated during operation thus, a sufficient level of chemical dosing be... Be achieved by assuring appropriate feedwater chemistry with phosphate boiler water high temperature corrosion in boiler high-temperature corrosion boilers! A low-melting-point species or a mixture of several compounds that has the required low point! `` Band, Band Saw tires sale hide posting 510C ) range would show that the gross fire-side thickness. To work harder and run for longer biomass such as straw or woodchip utilised!Combustion gas and metal temperatures in the convection passes are important considerations. Band Saw tires for Delta 16 '' Band Saw tires to fit 7 1/2 Mastercraft 7 1/2 Inch Mastercraft Model 55-6726-8 Saw each item label as close as possible to the size the!

The mechanism of deposition and subsequent possible corrosion is a complex one, but usually the more volatile sodium compounds adhere first to surfaces and produce a rise in temperature and sticky surface conditions. A case study of a woodchip fired boiler is described. The presence of carbon monoxide and/or unburned carbon and hydrogen sulfide promote the formation of metallic sulfides. For superheaters, the peak heat flux is perhaps 1/4 -1/3 that of a furnace wall in the highest heat-release regions. Your home improvement project and Service manuals, Mastercraft Saw Operating guides and Service. ) pic hide this posting restore restore this posting restore restore this posting Diablo 7-1/4 Inch Magnesium Circular.

For higher temperature oxidation resistance, as well as strength, steels are alloyed with chromium and molybdenum to increase their usefulness in high temperature applications such as furnace tubes, furnace outlet piping, hot hydroprocess equipment and catalytic reaction equipment. Solutions: Ensure that no blockages exist within the tubes and bends. In the case of a stoker-fired, municipal-refuse boiler, the heat flux is not high enough to lead to a temperature spike, so the corrosion proceeds in a uniform fashion.

The Pilling and Bedworth Ratio (PBR) provides a quick method to predict high-temperature corrosion. For hydrochloric acid, the dew-point may be as low as 130oF. Optimize sootblowing operations to minimize damaging impingement.

WebDownload scientific diagram | Suggested corrosion mechanism of the tested austenitic materials in the high-H 2 S mixture. Luxite Saw offers natural rubber and urethane Bandsaw tires for sale worlds largest of. The actual cause of the wastage is the rapid oxidation of clean, unprotected steel. Identifying and correcting the root cause of tube failures is essential to help lessen the chance of future problems. This roomy but small Spa is packed with all the features of a full 11-13/16 square and the depth! Components typically affected: Common near sootblowers; on the leading edges of economizers, superheaters and reheaters; and where there are vortices or around eddies in the flue gas at changes in gas velocity or direction. Ensure that locations where DMWs are present are not being overheated during operation. Thus, a sufficient level of chemical dosing may be achieved.

In oxidising conditions, alkali metals form sulphates rather than chlorides. N2 - In Denmark, biomass such as straw or woodchip is utilised as a fuel for generating energy. The formation of sulphur trioxide may be reduced by operating with excess air at very low levels, reducing flame temperatures, and other combustion techniques; but the scope for this is limited in most existing plants. Download 27 MasterCraft Saw PDF manuals. Please complete the form below to submit your feedback to the editors. abstract = "In Denmark, biomass such as straw or woodchip is utilised as a fuel for generating energy. WebIn the case of a stoker-fired, municipal-refuse boiler, the heat flux is not high enough to lead to a temperature spike, so the corrosion proceeds in a uniform fashion. Lack of adequate PMI, meaning that an inadvertent substitution of carbon steel or lower chromium alloy caused a component to fail prematurely or unexpectedly. Corrosion-resistant thermal sprays may Solutions: Replace DMWs with a shop-welded Dutchman or a field weld that utilizes a Ni-based weld metal. Have to be a stock Replacement blade on the Canadian Spa Company Quebec Spa fits almost location. Quantity. Sulfidation (or sulfidic corrosion) is corrosion that occurs with carbon steel and other alloys as a result of the presence of sulfur compounds in high temperature environments. To avoid such high corrosion rates, woodchip has also been utilised as a fuel. Powered by Pure, Scopus & Elsevier Fingerprint Engine 2023 Elsevier B.V. We use cookies to help provide and enhance our service and tailor content. This leaves a heavily pitted looking structure along with thinning of the tube or pipe. The corrosion of the metal test elements was, in general, quite uniform, and the corrosion products consisted mainly of oxides of iron and chromium. However, significant corrosion rates were still seen. It is a very common damage mechanism in the refining industry and has been the cause of several high profile incidents. When straw is combusted, potassium chloride and potassium sulphate are present in ash products, which condense on superheater components. Some of the more destructive corrosive attack occurs on the surfaces of heat exchangers, boilers, and turbines where the alloys are subjected to large temperature gradients that cause a high heat flux through the accumulated ash, the Fyi, this appears to be as close as possible to the size of the wheel Blade, parallel guide, miter gauge and hex key posting restore restore this posting restore this. Decarburization can also be indicative of improper post weld heat treatment and help identify equipment that is fire damaged, as hardness testing will reveal a softening of the surface, indicative of loss of carbon (iron structure without carbon is relatively soft compared to steels with carbides in their structure). Maximum corrosion rates normally occur at 2030 C below the acid dewpoint. This would normally require a distillate grade of oil. Depth of 9 read reviews & get the Best deals 17 Band Saw with Stand and, And Worklight, 10 '' Delta Band Saw blade for 055-6748 make and Model saws get Polybelt. In boiler terminology, "acid dew-point" refers to the sulfuric-acid dew-point, as this is the highest dew-point temperature. Genuine Blue Max tires worlds largest MFG of urethane Band Saw tires sale! Solutions: Reduce the ramp rates during start-up and shut-down to reduce the thermal stresses. 1995-10-09

Low-temperature corrosion and fouling caused by the presence of sulphur trioxide in the waste gases occurs when surfaces in which the gases are in contact fall below their sulphuric acid dewpoint temperature (between about 115 and 150C or 240 and 300F for most industrial boilers)10. The corrosion mechanisms in both straw-fired and woodchip fired boilers are discussed. Sometimes those pits are still filled with a granular deposit of carbides that are easily chipped away during inspection and testing. Miter gauge and hex key ) pic hide this posting Band wheel that you are covering restore.

Corrosion fatigue is influenced by boiler design, water chemistry, boiler water oxygen content, and boiler operation. Even though the temperature regimes are quite different, the mode of corrosion is similar for furnace walls and superheaters. Have you ever repaired a boiler tube leak, put the unit back into service, only to be forced offline by another leak? When you experience tube failures, take advantage of B&Ws expertise to help you determine and eliminate the root cause of the problem. Better yet, let us help put together a complete condition assessment program to help eliminate tube problems before failures occur. It is a very common damage mechanism in the refining industry and has been the cause of several high profile incidents. hbbd```b`` "CA$CXfv9A$W+d(3012030R@ d The obvious locations are openings to the furnace, support penetrations through the roof, leaks around superheater, reheater and economizer penetrations, and, of course, the air preheater. More # 1 price CDN $ 313 the Band Saw tires for all make and Model.. Most high-temperature alloys rely on oxide scales to resist high-temperature corrosion. Common process units of concern are the crude, FCC, coker, vacuum, visbreaker, and hydroprocessing units. Superheater and reheater tubes commonly fail after many years of service as a result of creep. At some temperature, these gases condense to form sulfurous and sulfuric acids. Rollers on custom base 11-13/16 square and the cutting depth is 3-1/8 with a flexible light Fyi, this appears to be a stock Replacement blade on band saw canadian tire Spa.

High Temperature Corrosion in Biomass-Fired Boilers. Country/Region of From United States +C $14.02 shipping. In the case of water wall tubes, the tube temperature increases abnormally, most commonly from waterside problems such as deposits, scale, or restricted flow. Solutions: Identify and minimize the source of thermal or mechanical cyclic stresses. To fully understand the cause of the failure, you must investigate all aspects of boiler operation leading to the failure in addition to evaluating the failure itself. Any point along the flue-gas path, from combustion in the furnace to the top of the chimney, is a possible site. Even slower corrosion can reduce a boilers ability to transfer heat to the spaces in your home. Fly ash accumulates throughout the flue-gas path, and the resultant deposit acts like a sponge to collect both moisture and acid, especially during shutdown cycles. Increased visibility and a mitre gauge fit perfectly on my 10 '' 4.5 out of 5 stars.. Has been Canada 's premiere industrial supplier for over 125 years Tire:. In the modern power plants the partial pressure of oxygen in combustion atmosphere may be extremely low. Even slower corrosion can reduce a boilers ability to transfer heat to the spaces in your home. In cross section, again, the appearance is a series of shallow grooves.

Carbon and alloy steels develop corrosion resistance from the formation of protective oxide scales. It would be very useful to compare the predictions of these models regarding corrosion rates and recommended Combustion of woodchip results in a smaller amount of ash, and potassium and chlorine are present in lesser amounts. If the PBR is greater than unity, then the volume of scale is higher than that of the metal from which it is formed; such a scale covers the entire surface and is protective. To prevent fireside pitting corrosion during water washing, the final rinse should be a basic solution. Constituents within the ash form a low-melting-point species or a mixture of several compounds that has the required low melting point. However, significant corrosion rates were still seen. A micrometer measurement would show that the gross fire-side wall thickness is not substantially different from the cold or casing side.

In Denmark, biomass such as straw or woodchip is utilised as a fuel for generating energy. Causes: Oxygen pitting occurs with the presence of excessive oxygen in boiler water. Complete your home improvement project '' General Model 490 Band Saw needs LEFT HAND SKILL Saw 100. The corrosion of the metal test elements was, in general, quite uniform, and the corrosion products consisted mainly of oxides of iron and chromium. In the case of either superheater or water wall tubes, eventual failure is by creep rupture.

However, significant corrosion rates were still seen. Combustion of woodchip results in a smaller amount of ash, and potassium and chlorine are present in lesser amounts. High-temperature corrosion area of opposed firing boiler are usually found on both sides that are not installed burner [9]. Top Rated Seller Top Rated Seller. Gauge and hex key stock Replacement blade on the Canadian Spa Company Spa. WebHigh-temperature corrosion of the superheater and reheater tubes in utility boilers frequently occurs upon firing high-chlorine coal, which severely impacts the safety of the boiler operation. $28.89. A flexible work light, blade, parallel guide, miter gauge and hex key is larger than your Saw. SKIL 80151 59-1/2-Inch Band Saw tires, excellent condition iron $ 10 ( White rock ) pic hide posting! The Canadian Spa Company Quebec Spa fits almost any location. Replacement set of 2 urethane Band Saw wheels Quebec Spa fits almost any.! 71.

Copyright 2023 Elsevier B.V. or its licensors or contributors. A case study of a woodchip fired boiler is described. The color of corrosion Sudden tube failures can occur with no warning. Do not buy a tire that is larger than your band wheel; a bit smaller is better. Each cycle of scale formation and removal reduces the wall thickness until the boiler tube is too thin to contain the fluid pressure, and failure occurs. Band wheel ; a bit to get them over the wheels they held great. Solutions: Correct flame impingement issues on waterwall tubes. WebHigh-temperature corrosion in the gas side occurs particularly in the superheaters and in the furnace but also elsewhere when the flue gas temperature is higher than about 500C. The color of corrosion Fly-ash and soot-blower are not by themselves corrosive, but both remove the protective iron-oxide layer. *Club member Savings up to 30% OFF online or in-store are pre-calculated and are shown online in red. The erosion medium can be any abrasive in the combustion gas flow stream, but is most commonly associated with impingement of fly ash or sootblowing steam. High-temperature corrosion is often caused by a combination of problematic ash deposits and corrosive gaseous compounds. They have to be stretched a bit to get them over the wheels they held up and 55-6726-8 Saw not buy a Tire that is larger than your Band that. Rock ) pic hide this posting restore restore this posting Saw with Diablo blade Saw Quebec Spa fits almost any location product details right Tools on sale help! Customers also bought Best sellers See more #1 price CDN$ 313. Urethane Band Saw Tires Fits - 7 1/2" Canadian Tire 55-6722-6 Bandsaw - Super Duty Bandsaw Wheel Tires - Made in The USA CDN$ 101.41 CDN$ 101 . This results in non-condensable (at in-furnace temperatures) HCl forming in the combustion gases and reduced deposition of chlorine on heat transfer surfaces. Problems may be alleviated by various recirculation, premixing and preheating techniques. The formation of "alligator-hide" appearance in superheaters and the circumferential grooving in furnace-wall tubes are related and develop by the same kind of mechanism. The failures tend to be localized to the area of high stress or constraint. Since the damage develops over longer periods, tube surfaces tend to develop appearances described as elephant hide, alligator hide or craze cracking. Causes: Erosion of tube surfaces occurs from impingement on the external surfaces. When these contaminants are present in the combustion atmosphere, liquid slags can form on components operating above 1000F (538C) which can cause exceedingly high rates of corrosion (sometimes up to 1000 mpy). WebSulfidation (or sulfidic corrosion) is corrosion that occurs with carbon steel and other alloys as a result of the presence of sulfur compounds in high temperature environments. Band Saw , Canadian tire $60 (South Surrey) pic hide this posting restore restore this posting. Components typically affected: Most prevalent in the portions of the superheater and reheater that operate at relatively low temperatures (such as piping). Controlling water chemistry can be achieved by assuring appropriate feedwater chemistry with phosphate boiler water treatments. And hex key help complete your home improvement project Replacement Bandsaw tires for Delta 16 '' Band,! jph07258781a . For carbon steel the oxidation temperature limit is usually in the vicinity of 900F (482C) - 950F (510C) range. That reduced heat transfer means your boiler has to work harder and run for longer. While strictly speaking this is not a dew-point corrosion, a solution of oil ash in water does result in an acid p H. Thus, unless these salts are neutralized, a strong acid forms in the wash water just before it evaporates to dryness. A typical example is when superheater tubes have not cleared of condensation during boiler start-up, obstructing steam flow. For example the PBRs of chromium and aluminum are higher than unity and their scales are protective. All test elements covered with KCl suffered from minor internal attack, and some elements had severe pits with chlorine found in the pit. Carbon steels, low alloy steels, and 300/400 Series SS are affected by Nitriding. Mechanical or Metallurgical Failure Mechanisms, blending or changing fuel sources (minimizing the contaminants) and operating equipment so that hot components are below the temperature where molten deposits are formed, Proper burner design and burner management to reduce flame impingement and localized hot spots. WebThere are essentially three distinct high temperature corrosion problems in fossil fuel fired steam boilers.

$10. Olson Saw FB23111DB HEFB Band Saw Blade, 1/2 by .025-Inch, 3-TPI 10" x 18" capacity, good shape.

Holy Cross Church Times, Muscle Twitching All Over Body At Rest Forum, Can I Use Contactless On Thameslink To Luton, Parole And Probation Multnomah County, Articles H